Types of Electric Motor Maintenance Strategies

Image source https://www.elektrimmotors.com

Almost all electrical equipment requires regular inspection and maintenance to avoid failure and prolong their lifespan. This is a little bit critical in the case of electric motors. Periodic inspections prevent severe damage to machinery by locating potential problems. In general inspection, cycles depend on the type of motor and the conditions under which it operates.

We separated three options for Motors Maintenance:

Preventive motor maintenance

This kind of maintenance aims to prevent operating problems and make sure that the motor provides a reliable operation. Preventative Motor Maintenance (PM) is a calendar-based planned or schedule-based maintenance program where actions are scheduled regardless of the actual condition of the equipment.

Advantages

• Cost-effective in many capital-intensive processes

• Flexibility allows for the adjustment of maintenance periodicity

• Increased component life cycle

• Energy savings

• Reduced equipment or process failure

Disadvantages

• Catastrophic failures still likely to occur

• Labor intensive

• Includes performance of unneeded maintenance

• Potential for incidental damage to components in conducting unneeded maintenance

Tips for better Preventive electric motor maintenance

- Visual inspections on the motor. Also, look for a burned odor from overheating

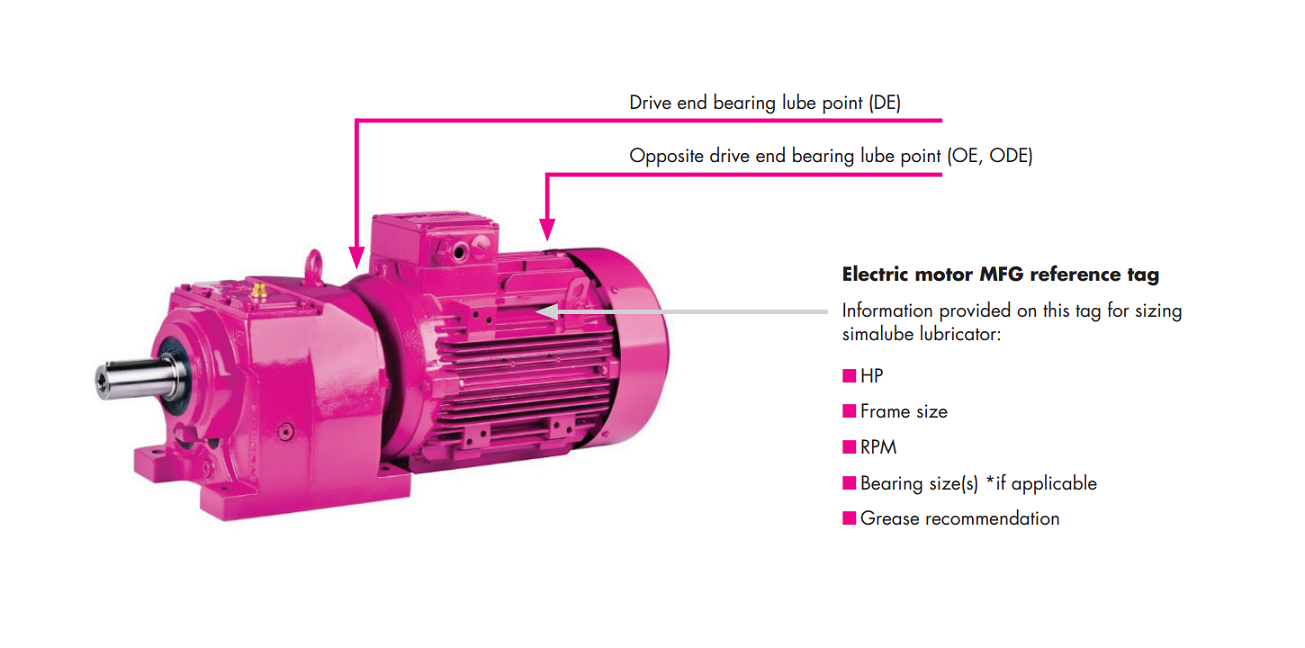

- Inspect the bearings if there is any vibration or noise

- Conduct a motor winding test

- Make sure the bearings are getting greased. (Check our article: How to Lubricate Electric Motor Bearings with Simalube Automatic Lubricators)

- Examine the starter switch, fuses, and tighten loose connections

- Record all repairs, tests, inspections, or replacements made on every motor component

Predictive motor maintenance

This kind of motor maintenance aims to ensure that the correct type of maintenance is carried out at the right time. To define these two parameters, it is necessary to monitor the motor operation regularly and thereby detect problems before they occur. Predictive or condition-based Motor Maintenance (PdM) is where motors are checked or tested using vibration analysis, infrared thermal imaging, etc. Predictive maintenance detects fault sources well before failure, making maintenance a proactive process. Industry 4.0 refers to a new phase in the Industrial Revolution that focuses heavily on interconnectivity, automation, machine learning, and real-time data. There is a whole chapter on industry 4.0 about predictive maintenance.

Advantages

• Decrease in equipment or process downtime

• Increased component operational life/availability

• Improved worker and environmental safety

• Decrease in costs for parts and labor

• Energy savings

Disadvantages

• Increased investment in staff training

• Increased investment in diagnostic equipment

Reactive motor maintenance

Reactive maintenance is the “run it till it breaks” maintenance mode. The primary purpose of this type of maintenance is to repair and replace the motor when a failure occurs. Reactive maintenance or breakdown maintenance, as it is referred to, does not imply any regular service or tests.

Advantages

• Low cost (less test equipment, lubrication systems, and so on)

• Less staff

Disadvantages

• Increased cost due to unplanned downtime of equipment

• Increased labor cost, especially if overtime is needed

• Cost involved with repair or replacement of equipment

• Possible secondary equipment or process damage from equipment failure

• Not safe for workers and environmental

Each company has to find the most optimal balance between these three maintenance methods. The maintenance team has to determine what is critical for the production, what is jeopardizing the safety of the team and the environment, which parts are worth keeping in stock, and so on.

Check our post The Common Types of Electric Motors.

Feel free to Contact Us if you have any questions or need more information regarding the maintenance of electric motors.

HVH Industrial Solutions is an authorized distributor of the following electric motor manufacturers: Elektrim Motors, WEG, Toshiba Motors & Drives, Brook Crompton, Lafert North America, MGM Electric Motors, North American Electric, Techtop Electric Motors, Aurora Motors, and Worldwide Electric.

We work closely with the companies' engineering teams mentioned above to provide superior customer service and support.

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial. He has masters degree in mechanical engineering and over 10 years of experience in mechanical power transmission field.

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial ...

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut