The Common Types and Sizes of V-Belts

Image source: https://www.bandousa.com

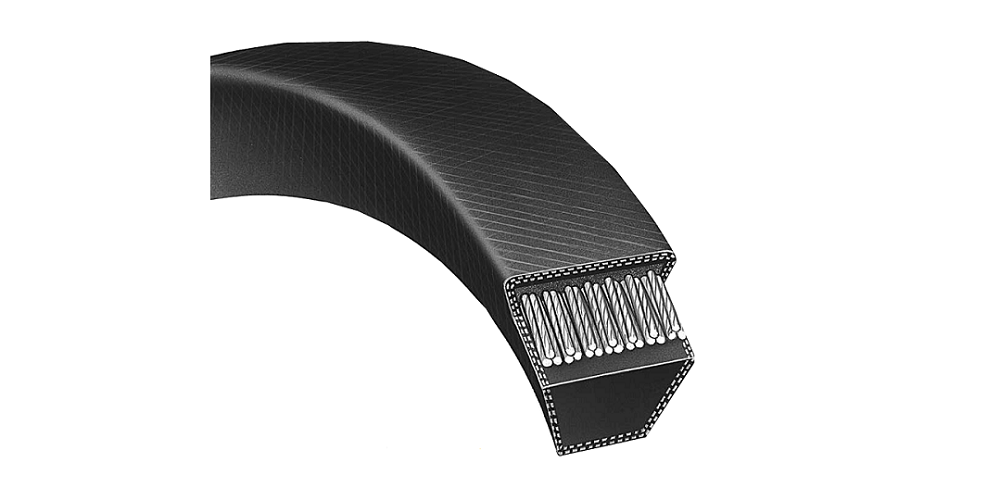

When we want to transfer power from one shaft to another, we use power transmission devices, such as belts, chains, and gears. In today's article, we will discuss a highly flexible and efficient power transmission device known as V-belt. V-belts get their name from their trapezoidal shape, which helps them wedge into the sheaves. Twisted synthetic fibrous tensile chords, compressed by synthetic rubber form a typical V-belt, rendering it strength and flexibility. To break the bending resistance even further, keep the operating temperature lower, and give higher capacity, V-belts come in cogged construction. As opposed to chains, V-belts do not require lubrication or maintenance. They also solve slippage and alignment problems.

The types of V-belts and their standard sizes:

There are three common V belt types: Classical V-belt (classified by their dimensions from A to E), Narrow V series (ranked by their sizes 3V, 5V, and 8V), and light-duty Fractional Horsepower belt (classified by their dimensions 2L, 3L, 4L, 5L). The letter X classifies their counterpart cogged belt. For example, the Classical V cog belt will be 3VX, 5VX, etc.

Classical V-belt:

The conventional V-belt is the most common type and has been around the longest. The Initial classical V design replaced leather belts by taking over their applications in various industries, such as agriculture, ventilation, and industrial machinery. Classical V-belts can cover a load range from fractional(less than 1 HP) to 500 horsepower. They are less efficient than narrow V-belts and generally contribute to higher bearing loads. However, classical V-belts have a high tolerance for poor operating conditions.

The general part number format is the cross-section size and the inside length in inches ( e.g., B50 is a B section of 50 inches inside measurement).

General cross-sectional dimensions that are used in the US are shown below.

Narrow V series:

Narrow belts are optimum for load transfer and force distribution because of their greater depth to width ratio. That’s their advantage over classical V belts. Narrow belts are also suitable for drives with high belt speeds, again, for their powerfully compact size. Narrow belts can transmit up to three times the horsepower of classical V-belts in the same drive space. They can handle drives from 1 to 1000 horsepower.

Part number designation for wedge belts is shown in belt top width followed by the nominal outside length in inches. The numerical prefix indicates the belt top width in one-eighth of an inch. For example, the 5V500 part number indicates a 5/8” top width with a 50.0” outside length.

General cross-sectional dimensions that are used in the US are shown below.

Fractional Horsepower Belt:

FHP light-duty V-belts are often used as single belts on drives of 1 horsepower or less. Its design is for relatively light loads. The most common applications for this V-belt type are domestic washing machines, small fans, refrigerators, and garage equipment. Light V-belts should never be used on any heavy-duty industrial applications, even if they seem to fit the classical or narrow V-belt pulley grooves.

Part number designation for FHP belts is similar to wedge. They are identified with a 2L, 3L, 4L, or 5L prefix. The numerical prefix indicates the belt top width in one-eighth of an inch, followed by the nominal outside length in inches. For example, the 3L300 part number indicates a 3/8” top width with a 30.0” outer length.

General cross-sectional dimensions that are used in the US are shown below.

Feel free to Contact Us if you have any questions, need more information or if you are interested in purchasing a V belt. HVH is a power transmission distributor doing business in the USA.

Check out our post Types Of Synchronous Belt Profiles and Nomenclature.

Brands HVH offers Bando, Bestorq, Continental Contitech, and Mitsuboshi Belting.

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial. He has masters degree in mechanical engineering and over 10 years of experience in mechanical power transmission field.

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial ...

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut