Things To Know Before Installing Planetary Gear Reducers by Rossi

Image source https://www.rossi.com

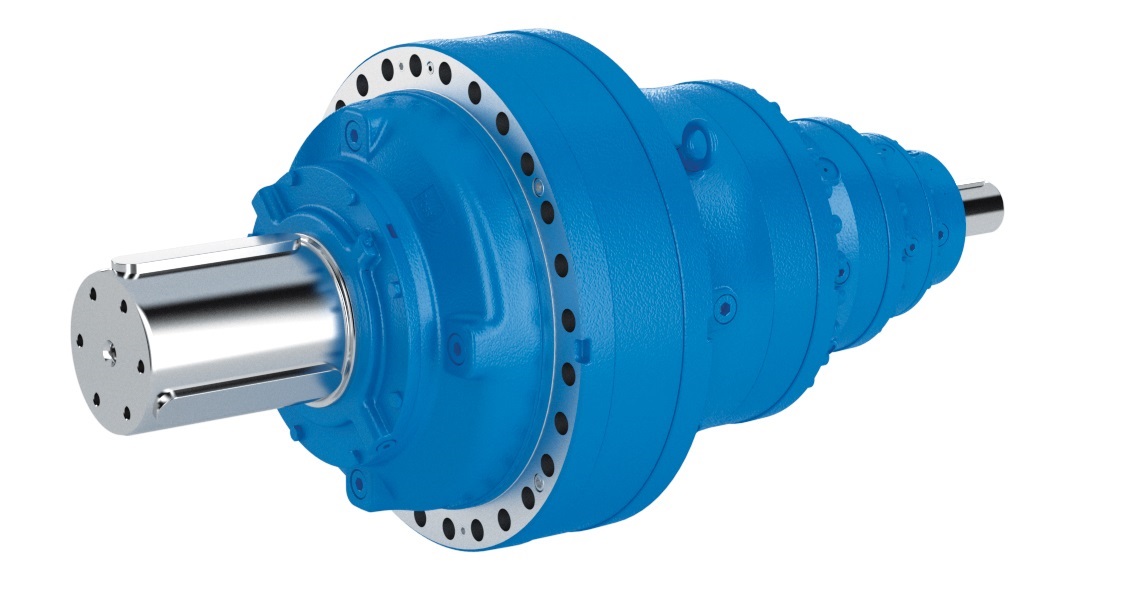

A planetary gear reducer is a planetary gearbox that aims to transmit maximum torque in the most compact form. It decreases the number of motor revolutions and ensures high torque through the speed sensor. As an essential mechanism in a power transmission system, installation and maintenance strategies of planetary gear reducer should be adequately organized to avoid problems that people often meet. We provide the main tips that should be considered before installing a planetary gear reducer.

First, some vital information.

Operating conditions

Gear reducers are designed for industrial applications at ambient temperature 0 ÷ + 40 °C (with peaks at -20 °C and + 50 °C), with a maximum altitude of 1 000m.

This is how it is supplied.

Every gear reducer is provided with a nameplate in anodized aluminum containing the preliminary information necessary for the correct identification of the product; the nameplate must not be removed and must be kept integral and readable. All nameplate data must be specified on eventual spare part orders. Overhanging free shaft ends and hollow shafts are treated with protective anti-rust, long-life oil. All internal parts are protected with protective anti-rust oil.

Lifting and Handling Instructions

First, make sure that the lifting equipment (e.g., crane, hook, eye bolt, straps, etc.) is suitable for the weight and size of the gear reducer (the product's weight is given in the nameplate). When lifting, use only the attachment point marked in the following figures. Pay attention to avoid lifting (max 15° during handling) and, if necessary, use additional straps only to balance the load. Do not use front threads at the input shaft ends to lift the gear reducers.

Storage

Surroundings should be sufficiently clean, dry, and free from excessive vibrations to avoid damage to bearings (excessive vibration should also be guarded during transit, even if within a broader range), and ambient storage temperature should be 0 ÷ +40 °C: peaks of 10 °C above and below are acceptable. The gear reducer filled with oil must be positioned according to the mounting position mentioned on the nameplate. Every six months, rotate the shafts (some revolutions are sufficient) to prevent bearings and seal ring damage. Assuming everyday surroundings and adequate protection during transit, the unit is protected for storage for up to 1 year. For a two-year storing period in usual surroundings, it is necessary to pay attention also to the following instructions: – generously grease the sealing, the shafts, and the unpainted machined surfaces, if any, and periodically control the conservation state of the protective anti-rust oil; – fill the gear reducers with lubrication oil.

Installation

Be sure that:

- That there are no damages on shafts and mating surfaces

- The used mounting position corresponds to the one stated on the nameplate

- The used mounting position corresponds to the one indicated on the nameplate

- The structure on which the gear reducer is fitted is plane, leveled, and sufficiently. Dimensioned to assure fitting stability and vibration absence, keeping in mind all transmitted forces due to the masses, the torque, and the radial and axial loads

- Carefully align the gear reducer with the motor and the driven machine (with the aid of shims if need be), interposing flexible couplings whenever possible.

- Avoid any obstruction to the air flow; heat sources near the gear reducer that might affect the temperature of cooling air and gear reducer (for radiation); insufficient air recycling and applications hindering the steady dissipation of heat.

- Position the gear reducer to allow a free passage of air for cooling both the gear reducer and motor (especially at their fan side)

- Verify that the gear reducer housing is dust-free to achieve an efficient heat dissipation

- Design is suitable to the environment (temperature, atmosphere, etc.). No applications are allowed in an aggressive environment having explosion danger.

- Gear reducers and gearmotors should be protected whenever possible and by appropriate means from solar radiation and extremes of weather; weather protection becomes essential when high, or low-speed shafts are vertically disposed of or when the motor is installed vertically with a fan uppermost.

- Mating surfaces (gear reducer and machine) must be clean and rough to provide a good friction coefficient. Remove by a scraper or solvent the eventual paint of the gear reducer on coupling surfaces and, especially in the presence of external radial loads or torque required, apply to lock adhesives.

- When external loads are present, use pins or locking blocks; if necessary.

- Before wiring up the Gearmotor, ensure that the motor voltage corresponds to the input voltage. If the direction of rotation is not as desired, invert two phases at the terminals. Y-À starting should be adopted for no-load starting (or minimal load), smooth starting current, low starting current, and limited stresses. If overloads are imposed for long periods or shocks or the danger of jamming is envisaged. Motor protection, electronic torque limiters, fluid couplings, safety couplings, control units, or other similar devices should be fitted. Usually, protect the motor with a thermal cut-out; however, where duty cycles involve a high number of on-load starts, it is necessary to utilize thermal probes for motor protection (fitted on the wiring); a magnetothermic breaker is unsuitable since its threshold must be set higher than the nominal motor current of rating. Connect thermal probes, if any, to auxiliary safety circuits. Use varistors and RC filters to limit voltage peaks due to contactors

Product Literature

Installation and maintenance of planetary gear reducer by Rossi

Also, you can check out our blog on Features and Applications of Planetary Gear Reducers by Rossi.

Feel free to Contact Us if you have any questions or need more information regarding the maintenance and installation of planetary gear reducers

HVH Industrial Solutions is an authorized Rossi distributor in the US. We work closely with their engineering team to provide superior customer service and engineering support.

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial. He has masters degree in mechanical engineering and over 10 years of experience in mechanical power transmission field.

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial ...

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut