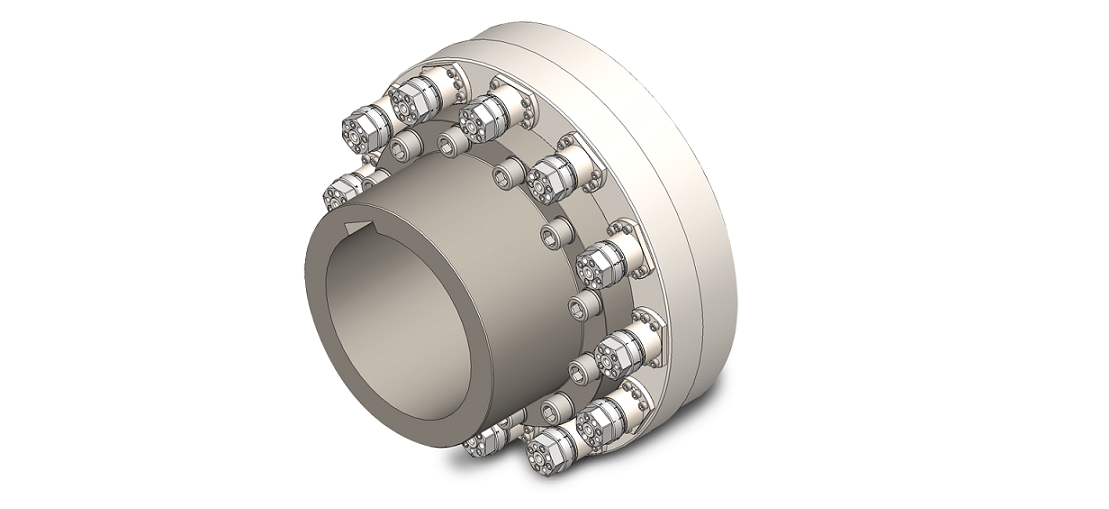

What is a Torque Limiter & Common Types

Image source https://www.bibbyturboflex.com

Imagine working in your garden, trimming some trees, looking excellent, and choosing to get rid of the branches with a wood shredder. What happens if metal gets into the wood shredder by some mistake? It's stuck, and as a result, it overloads and fails. The engine burns out, and you have to get a new machine. Was there a chance to avoid that? Well, yes. Firstly pay attention to what you're putting in there, and secondly, make sure that the machine has a torque limiter.

What's a torque limiter? In simple words is a machine component that protects mechanical equipment from damage by mechanical overload. To make it even more straightforward, it's a device that would stop the engine in that wood shredder from burning out. How? Say the metal got in, and you can hear weird sounds because the machine can't shred metal. The torque limiter automatically shuts down the powertrain to avoid something nasty, like the engine burning out or an explosion. A limit switch can provide the limiters with rotating elements (balls or rollers). This gives the limiter control of the motor drive system and stops the machine, e.g., Emergency Stop.

There are two options with Torque limiters. The ones that allow you to reset it automatically or manually and re-engage after the torque goes back to normal range and don't need to be reset.

The ones that can be reset are called Disconnect types. There are 4 of those: shear pin, Synchronous magnetic, Ball detent, and Pawl and spring. Let's take a quick look at each.

Shear pin

This one is a killer. In short, it sacrifices a mechanical component to save the whole machine. In a bit more engineering terminology, a shear pin is a mechanical detail designed to allow a specific outcome to occur once a predetermined force is applied. It can either function as a safeguard designed to protect other parts or as a conditional operator that will not allow a mechanical device to operate until the correct force is applied.

Synchronous magnetic

A synchronous magnetic torque limiter uses permanent magnets mounted to each shaft, with an air gap between them. They are very fast-acting but may have more backlash than mechanical types. Because there is no mechanical contact between the two shafts, they are also used to transmit torque through a physical barrier like a thin plastic wall. In some models, the torque limit may be adjusted by changing the gap between the magnets.

Pawl and spring

This mechanical type uses a spring to hold a drive pawl against a notch in the rotor. It may feature automatic or manual reset. A compression adjustment on the spring determines the torque limit.

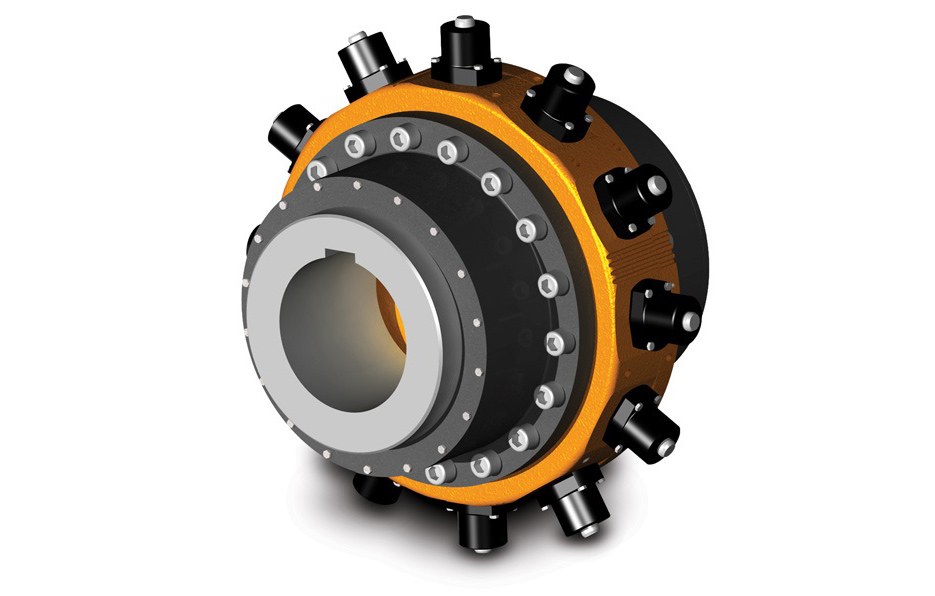

Ball detent

A ball detent type limiter transmits force through-hardened balls, which rest in detents on the shaft and are held in place with springs. An over-torque condition pushes the balls out of their detents, thereby decoupling the shaft. It can have single or multiple detent positions or a snap-acting spring, which requires a manual reset. There may be a compression adjustment to adjust the torque limit.

Now to the ones that don't need to be reset. They are Friction plate, Magnetic plate, and Magnetic hysteresis. Let's take a look at these as well.

Friction plate

This type is similar to a friction plate clutch. Over-torque will cause the plates to slip. A simple example is found in a fixed-spool fishing reel, where the slipping torque is set by a giant hand nut so that the reel will turn and allow more line to unwind before the line breaks under the pull of a fish.

Magnetic particle

A magnetic particle clutch can be used effectively as a torque limiter. The torque setting reasonably approximates a linear relationship with the current passing through the windings, which can be statically or dynamically set depending on needs.

Magnetic hysteresis

This type is non-synchronous in regular operation, so there is always some slippage.

In short, Torque limiters are lifesavers. Instead of going through the pain of spending crazy amounts of money on getting a new machine (or even worse), you come out of this unfortunate situation of a component failure relatively easily, cheaply, and even comfortably. It is one thing to replace a component that failed and get a new machine. You do the math.

You can check our post the Working Procedure of Modular Torque Limiters.

Feel free to Contact Us if you have any questions, need more information or if you are interested in purchasing a torque limiter.

HVH Industrial Solutions is an authorized distributor of Bibby Turboflex, Warner Electric, Dalton Gear, Rota Free / Compomac, and Brunel Corp.

We work closely with the above engineering teams to provide superior customer service and engineering support.

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial. He has masters degree in mechanical engineering and over 10 years of experience in mechanical power transmission field.

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial ...

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut