What Types of DESMI Pumps are Used in Desalination Plants to Collect Seawater

Image source https://www.desmi.com

Water has been and continues to be the most vital necessity for the population and environment in the world. Very often, people feel the deficiency of water; the thing is that 98 percent of the planet's water is salty. Therefore, the world's local authorities and industrial and agricultural producers have started using seawater as a source. In the up-to-date world, desalination pumps are considered the perfect solution to make salty water fresh.

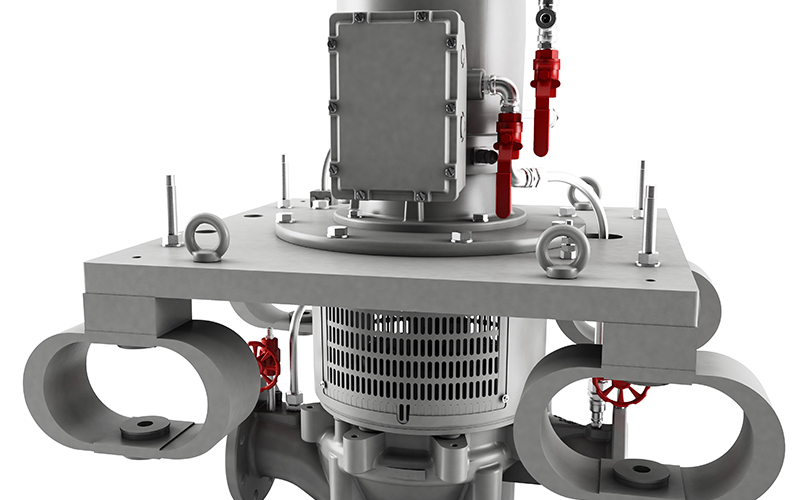

Desalination is a process for producing drinking water and service water from seawater. Desmi-manufactured DSL centrifugal pumps are a practical choice for water distillation systems or reverse osmosis (RO) treatment. The DSL pumps are single-stage, double-suction, vertical, and centrifugal pumps.

Product Description

DSL is a single-stage pump with stainless steel shaft, mechanical shaft seals, and a closed impeller of the double-suction type. The pump is a so-called "in-line" type, i.e., suction and pressure branches are mounted on the centerline. It is vertical with an impeller of the double-suction type with double-curved blades, having a helical pump casing in one casting.

The pumps are equipped with an electric motor with protection class IP 54. This means that the motor is protected from penetrating dust and that splashes of water without pressure do not ruin the motor. Suppose the pumps are installed in explosive areas. They must be equipped with explosion-proof motors. The motors are designed for continuous operation at a maximum ambient temperature of 40°C.

Product Benefits

-

High efficiency

-

Low NPSH values

-

Advanced double-suction impeller

-

Up to 5400 m3/h, pressure up to 90 mLC

-

The inlet is placed in line with the outlet.

-

The design of the suction side provides for a perfect flow.

Frost Protection

Pumps that are not in operation during the frost should be drained to prevent frost damage. Remove the plug at the bottom to drain the pump. It is also possible to use anti-freeze liquids in routine constructions. For safety purposes, the pump can only operate against a closed discharge valve for a short time (max. 5 minutes and at a max. temperature of 80°C for standard pumps). Otherwise, there is a risk of damage to the pump and, at worst, of a steam explosion. If the pump is not monitored, installing a safety device is recommended.

Product Literature:

DSL-Centrifugal-Pumps-Operation-and-Maintenance-Instructions

In-line-Double-Suction-Centrifugal-Pump-DSL

Check out our other article Emergency Military Pumps By Desmi.

HVH Industrial Solutions is an authorized distributor of Desmi Pumps. We work closely with their engineering team to provide superior customer service and engineering support.

If you have any questions, write us via live chat, call or send us a quote request. The HVH team is always ready to help you.

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial. He has masters degree in mechanical engineering and over 10 years of experience in mechanical power transmission field.

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial ...

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut