Amerigear Mill Spindles

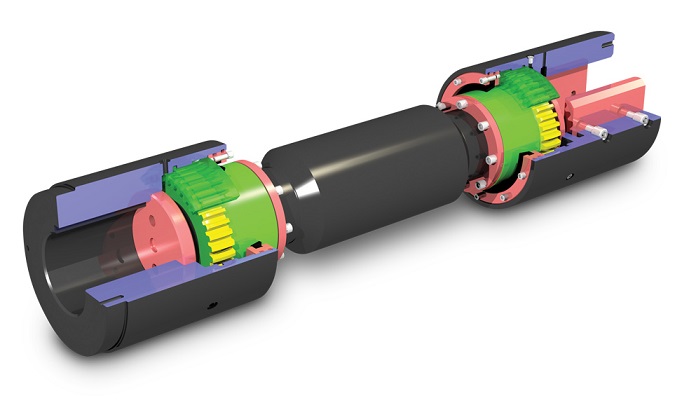

Gear spindles are critical components of the drive train. The performance of the drive spindles can influence strip quality and thickness control. The modern, efficient gear-type spindles require less maintenance and are economical enough. Mill spindles can be used for heavy-duty metal rolling main drives and auxiliary equipment.

We also offer custom-designed Amerigear mill spindles for a particular application, where the spindle materials, heat treatment, hardening process, misalignment capabilities, optional design features, and custom modifications are considered.

HVH Industrial Solutions is an authorized distributor of Ameridrives.

We work closely with the Ameridrives engineering team to provide superior customer service and engineering support.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Manufacturers

Torque transmission is the lifeblood of countless machines and mechanisms. It enables the conversion of rotational energy into useful work, powering a multitude of applications ranging from heavy industrial machinery to intricate automotive systems. Gear spindles excel in this regard, ensuring a reliable and efficient transfer of torque

What Are Gear Spindles?

Gear spindles, at their core, are mechanical components designed to transmit torque between two non-collinear shafts. They consist of two main components: gears and a spindle. The gears are meticulously crafted to mesh with one another, transferring rotational force while accommodating misalignments between the shafts.

Key Features and Advantages

High Angular Misalignment Tolerance

One of the standout features of gear spindles is their exceptional tolerance for angular misalignment between shafts. This ability to accommodate misalignment enhances the flexibility of mechanical systems, allowing for smoother operation even in challenging conditions.

Robust Torque Capacity

Gear spindles boast a remarkable torque-carrying capacity, making them suitable for applications that demand substantial power transmission. Whether it's in heavy-duty industrial equipment or precision machinery, gear spindles provide the muscle needed to handle substantial torque requirements.

Suitability for Reversing Applications

Unlike some traditional torque-transmitting mechanisms, gear spindles are highly adept at handling reversing applications. Their design and engagement mechanism make them ideal for situations where rotational direction changes frequently, without compromising on efficiency.

Resilience Against Shock Loads

Modern industrial environments are rife with dynamic forces and sudden impacts. Gear spindles are engineered to withstand moderate to heavy shock loads, ensuring that the system remains operational even in rugged conditions.

Applications in Diverse Industries

Automotive Sector

In the automotive industry, gear spindles find application in various components such as steering systems, differentials, and transmission assemblies. Their ability to manage misalignment and transmit torque efficiently contributes to the overall performance and reliability of vehicles.

Industrial Machinery

Gear spindles play a pivotal role in industrial machinery, enabling the operation of conveyor systems, agitators, and heavy-duty pumps. Their robust design ensures consistent torque transmission, enhancing the productivity of manufacturing processes.

Marine Engineering

The marine sector benefits from the versatility of gear spindles in propulsion systems and marine thrusters. These devices endure the demanding conditions of maritime environments, delivering reliable torque transmission for efficient vessel propulsion.

Maintenance and Longevity

Proper Lubrication

Regular and proper lubrication maintenance is essential to ensure the longevity and performance of gear spindles. Adequate lubrication reduces friction, minimizes wear, and prevents overheating, ultimately extending the operational lifespan.

Monitoring and Inspection

Routine monitoring and inspection allow for the early detection of potential issues in gear spindle systems. Timely maintenance and corrective measures can prevent costly downtime and ensure uninterrupted operation.

Conclusion

In conclusion, gear spindles are essential for torque transmission, seamlessly bridging the gap between non-collinear shafts and enabling the efficient transfer of rotational energy. Their exceptional angular misalignment tolerance, robust torque capacity, and adeptness in reversing applications showcase their adaptability and versatility across diverse industries. From the automotive sector to industrial machinery and marine engineering, gear spindles play a pivotal role in enhancing performance and reliability.