Clutches

A clutch is a mechanical device used to engage and disengage power transmission from the driving shaft to the driven shaft. The driving shaft is connected to a power unit, and the driven shaft supplies the power output.

Clutches are met in equipment drives, where they are used to connect and disconnect shafts. These shafts carry gears or other machine parts that transmit power and motion to the rest of the system. When a certain shaft is engaged to the drive, the drive causes it to spin or move.

We offer a wide range of clutches such as Pneumatic & Hydraulic, Electromagnetic, Wrap Spring, Backstopping, Inline Mounting clutches, and more.

HVH Industrial works with the specialized engineering teams of manufacturers to meet the requirements and highest quality standards of our customers.

If you have any questions write us via live chat, (one of our team members will answer your questions), give us a call or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Clutches

Manufacturers

What is a Clutch

A clutch is a mechanical device used to connect and disconnect two rotating shafts. It is used to control the power and torque transfer from one shaft to the other, such as in a vehicle transmission, or to control the speed of a shaft, such as in a machine tool. The clutch can also disengage the shaft's drive so that the two shafts can be disconnected and reconnected without stopping the machine.

Clutches are typically used in applications where the power source needs to be disconnected quickly and efficiently. Clutches are used in most industrial settings to provide a smooth transition between starting, stopping, and reversing motion.

Clutches can also control the torque of a motor, allowing for precise control over the speed and power of a system. Industrial clutches are durable and reliable, so they can withstand the harshness of everyday use, allowing for quick and easy repairs. Industrial clutches come in various sizes and configurations, allowing custom solutions to fit any application.

Types of Clutches

Various types of industrial clutches are available, each of which has unique characteristics and applications. The most common types of clutches are: sprag, wrap spring, electromagnetic, and hydraulic.

Sprag Clutches

A sprag clutch is a type of one-way clutch that allows rotation in one direction while preventing it in the opposite direction. Sprag clutches are typically used as a failsafe in power transmission systems, as they lock when the torque or speed limit is exceeded. Sprag clutches are made up of several components, including an inner race, an outer race, and several sprags. The inner race is attached to the shaft, while the outer race is attached to a housing. The sprags, wedge-shaped pieces, fit into pockets in the inner and outer races. When the shaft rotates in one direction, the sprags move outward and engage the pockets in the inner and outer races, allowing the shaft to rotate. If the shaft rotates in the opposite direction, the sprags move inward and disengage from the pockets, preventing the shaft from rotating.

Wrap Spring Clutches

A wrap spring clutch consists of a coil spring wrapped around a rotating drum. By adjusting the tension on the coil spring, the clutch can control the speed of the shafts it is connected to. Wrap spring clutches work by allowing the coil spring to wrap around the drum and then applying pressure on the inner surface of the drum. This pressure creates friction between the drum and the coil, which creates torque. The torque can be adjusted by adjusting the tension on the coil. The amount of torque produced depends on the size and tension of the coil spring. Wrap spring clutches are most commonly used in automotive transmissions, which control the speed of the input and output shafts. It is also commonly used in conveyor systems and industrial machinery applications.

Electromagnetic Clutches

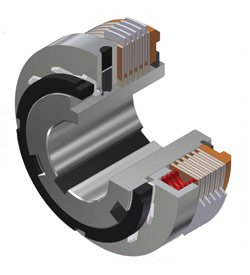

An electromagnetic clutch is a device used to connect or disconnect two rotating shafts, using the principles of electromagnetism to generate a mechanical force to engage the clutch. The mechanical force is generated by applying a current to an electromagnet, which is then used to attract an armature or other ferromagnetic material. The basic design of an electromagnetic clutch consists of two main components: the armature and the field. The armature is an electrically conductive material, usually steel, attracting the field when a current is applied. The field is made of an electromagnet surrounded by a magnetic coil. When current is applied to the armature plate, it creates a magnetic field that attracts the field plate, causing the two parts to engage. When the current is removed, the armature plate loses its magnetic field, separating the two parts. Electromagnetic clutches are commonly used in applications where precise control over power is needed, such as in automated factory machinery, elevators, and machine tools.

Hydraulic Clutches

A hydraulic clutch is a friction clutch that uses hydraulic fluid to transmit power from one component to another. It consists of two plates that are separated by a small gap and are connected by a series of valves and fittings that control the flow of the hydraulic fluid. The two plates are connected by a piston connected to a clutch plate. The clutch plate is connected to the driven load. When the piston is pushed, the hydraulic fluid is forced through the valves and fittings, which causes the clutch plate to rotate. This rotation causes the driven component to move, transmitting power from the power source to the driven component. Hydraulic clutches are used in many industrial applications, such as heavy-duty equipment, automotive, and marine applications. They provide a smooth, consistent connection between the power source and the driven load, which eliminates the need for frequent maintenance and repair.