Electric Vibrators

An Electric Vibrator efficiently converts electrical energy into rotational torque by generating a centrifugal force. They energize and maintain the movement of material by reducing both the friction factor between the bulk material and the equipment walls.

The vibrators are designed to be used for power vibratory equipment such as feeders, conveyors, and screeners, as well as to facilitate the flow of wet or dry materials in buns, hoppers, pipes, bulk trailers, and trucks.

The typical applications of electric vibrators include cement, chemical, aggregate, mining, concrete construction, and other industries.

We offer many electric vibrators such as Foot Mounted, Flanged, Mechanical, and High-Frequency.

HVH Industrial works with manufacturers' specialized engineering teams to meet our customers' requirements and highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Electric Vibrators

Manufacturers

What are Electric Vibrators?

Electric vibrators are mechanical devices designed to convert electrical energy into rotational torque. This torque generates centrifugal force, which drives the movement of materials in various industrial processes. By reducing the friction factor between the bulk material and the walls of the equipment, electric vibrators enhance material flow, ensuring efficient and continuous operations.

Electric vibrators consist of an electric motor with an unbalanced weight attached to its shaft. When the motor is activated, the unbalanced weight causes the shaft to rotate rapidly, creating centrifugal force. This force transfers to the equipment, causing it to vibrate and move the material. The design of electric vibrators ensures that they provide consistent and reliable performance throughout their operation.

Types of Electric Vibrators

Electric vibrators come in different types, each suited for specific applications. The common types of electric vibrators include:

Foot Mounted Electric Vibrators

Foot-mounted electric vibrators are versatile and can be easily attached to equipment like feeders and conveyors. They provide consistent vibrations and are easy to install.

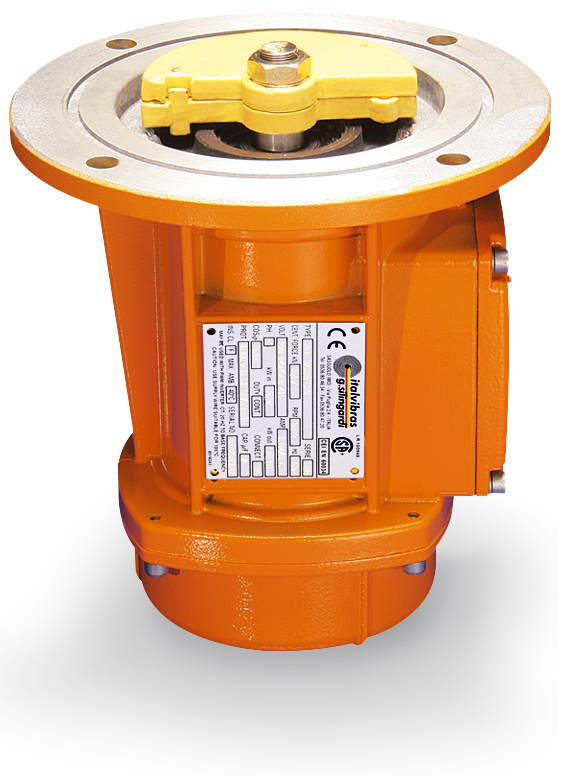

Flanged Electric Vibrators

Flanged electric vibrators are designed for applications that require a fixed mounting system. Their sturdy construction allows them to handle heavy loads and challenging operating conditions.

Mechanical Electric Vibrators

Mechanical electric vibrators are ideal for applications where electricity is not readily available or feasible. They are powered by an internal combustion engine and are commonly used in remote locations.

High-Frequency Electric Vibrators

High-frequency electric vibrators are designed for specialized applications that demand precise control over vibration frequencies. They are commonly used in the concrete industry for surface finishing.

Applications of Electric Vibrators

Electric vibrators find extensive applications in diverse industries due to their effectiveness in material movement and handling. Some of the key industries where electric vibrators are widely used include:

Cement Industry

In the cement industry, electric vibrators are employed in various processes such as material handling, mixing, and packing. They aid in ensuring the seamless flow of cement particles, preventing clogging and blockages in equipment.

Chemical Industry

The chemical industry utilizes electric vibrators to move and agitate chemicals in containers, ensuring proper blending and uniformity. This enhances the efficiency of chemical processes and minimizes manual labor requirements.

Aggregate Industry

Electric vibrators are indispensable in the aggregate industry for efficiently transporting and sorting different types of aggregate materials. They contribute to the smooth functioning of crushers, screens, and conveyors.

Mining Industry

In mining operations, electric vibrators are utilized to move and separate ores, minerals, and other materials. Their robust performance is vital for the smooth functioning of heavy-duty mining equipment.

Concrete Construction Industry

In the construction of concrete structures, electric vibrators are used to eliminate air bubbles and ensure the proper compaction of concrete. This enhances the overall strength and durability of the concrete.

Advantages of Electric Vibrators

Electric vibrators offer several advantages in industrial applications, including:

Enhanced Material Flow: Electric vibrators reduce friction and improve material flow, leading to increased productivity and efficiency in material handling processes.

Low Maintenance: These vibrators are designed to be low maintenance, minimizing downtime and operational disruptions.

Customizable: Electric vibrators can be customized to suit specific industry requirements, making them adaptable to various applications.

Energy Efficient: They convert electrical energy into mechanical energy with high efficiency, resulting in lower energy consumption.

Conclusion

Electric vibrators play a pivotal role in powering vibratory equipment and facilitating material movement in a wide range of industries. With their efficient conversion of electrical energy into rotational torque, they ensure the smooth flow of materials, contributing to the overall productivity and success of industrial processes.