Locking Assemblies

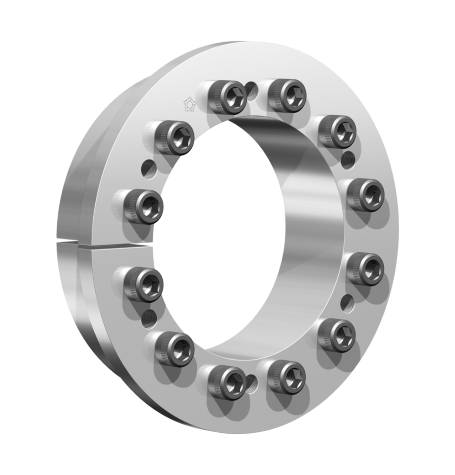

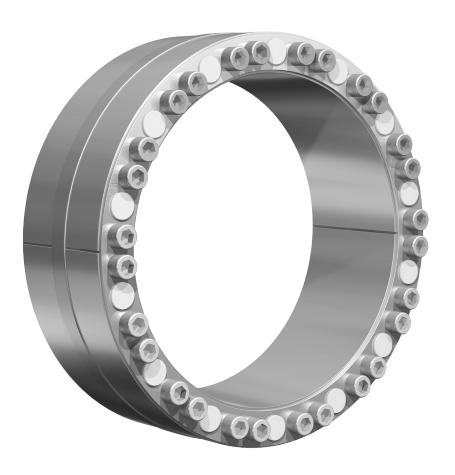

Locking Assemblies are friction-locked shaft-hub connections with high-quality standards. They are suitable for the precise fastening of all types of hubs, such as toothed gears, running wheels and chain sprockets, cam discs, belt and brake discs, levers, couplings, etc.

Compared to external clamping connections like shrink discs, locking assemblies are installed between the shaft and hub. They are available in various standard designs and sizes, as well as customized special solutions.

We offer a wide range of locking assemblies such as self-centering, locking assemblies for bending loads, for high forces and torque, high speeds, confined spaces, and others.

HVH Industrial works with manufacturers' specialized engineering teams to meet our customers' requirements and highest quality standards.

If you have any questions, write us via live chat, (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Locking Assemblies

Manufacturers

In many mechanical systems, it is essential to securely fasten rotating elements, such as gears or sprockets, to a shaft. Traditional methods like keyways or set screws may not provide the necessary precision, leading to issues like slippage, misalignment, or premature wear. Locking assemblies, on the other hand, offer a reliable and efficient solution to these challenges. These friction-locked assemblies adhere to high-quality standards, making them suitable for a wide range of applications including toothed gears, running wheels and chain sprockets, cam discs, belt and brake discs, levers, couplings, and more.

What are Locking Assemblies

Locking assemblies are mechanical devices designed to transmit torque between two components without the need for keys, keyways, or splines. They provide a secure and backlash-free connection, ensuring efficient power transmission in various applications. Locking assemblies are widely used in industries such as manufacturing, mining, energy, and automotive, where reliable power transmission is critical.

Locking assemblies consist of two main components: an inner hub and an outer sleeve. The inner hub has internal locking elements, while the outer sleeve has corresponding external locking elements. When the locking assembly is mounted between two shafts or components, torque is transmitted through the friction generated between the locking elements and the contact surfaces.

To engage the locking assembly, the outer sleeve is tightened using screws or hydraulic pressure, causing the locking elements to expand radially and create a tight grip on the shaft or component. This ensures a strong and reliable connection capable of transmitting high torque loads.

Key Features of Locking Assemblies

Locking assemblies boast several noteworthy features that contribute to their effectiveness and reliability:

High Torque Transmission

Locking assemblies can handle high torque levels due to their friction-locked design. This enables them to efficiently transfer rotational force between the shaft and the hub without slippage, ensuring optimal performance and preventing power loss.

Excellent Axial Load Capacity

In addition to torque transmission, locking assemblies provide excellent axial load capacity. This means they can withstand forces acting in the axial direction, maintaining the integrity of the connection even under heavy loads or sudden changes in direction.

Self-Centering Design

Locking assemblies have a self-centering design that facilitates easy and accurate alignment of the hub and the shaft. This feature simplifies installation and reduces the risk of misalignment, promoting smooth operation and extended component life.

Reusability

Locking assemblies can be easily disassembled and reassembled, making them a cost-effective solution. When maintenance or replacement is required, the locking assembly can be reused, minimizing downtime and reducing overall maintenance costs.

Advantages of Using Locking Assemblies

Utilizing locking assemblies in shaft-hub connections offers several advantages:

Enhanced Transmission Efficiency

Locking assemblies provide a secure and rigid connection, maximizing the efficiency of torque transmission. This reduces energy loss, enhances overall system performance, and improves the lifespan of the connected components.

Increased Torsional Stiffness

By eliminating slippage and play, locking assemblies enhance torsional stiffness. This is particularly beneficial in applications where precise positioning or synchronization is required, ensuring accurate and reliable operation.

High Torque Capacity

Keyless locking devices can transmit high torque loads, making them suitable for heavy-duty applications. They distribute the load evenly, reducing stress on individual components and enhancing overall system durability.

Vibration Damping

The frictional contact between the locking assembly components helps absorb and dampen vibrations, reducing noise and preventing damage caused by excessive oscillations. This feature is especially advantageous in high-speed or precision applications.

Versatility

Locking assemblies can accommodate a wide range of shaft diameters and component sizes, making them versatile and adaptable to different applications. They offer flexibility in design and allow for easy interchangeability.

In conclusion, locking assemblies are vital components that enable precise and reliable fastening of various hubs to shafts in mechanical systems. With their high-quality standards and friction-locked design, these assemblies offer numerous advantages such as efficient torque transmission, excellent axial load capacity, and self-centering capabilities. By utilizing locking assemblies, industries can enhance transmission efficiency, increase torsional stiffness, dampen vibrations, and simplify assembly and maintenance processes.