Pneumatic Vibrators

Pneumatic Vibrators are ideal for special environmental conditions in food, chemical, and pharmaceutical production, and applications requiring sanitary working conditions. They are available for high-temperature and low-temperature and caustic environments.

We offer a wide selection of pneumatic vibrators such as Turbine Vibrators, Ball Vibrators, Piston Vibrators, KA Internal Concrete Vibrators, Big Buster Vibrators, and more.

HVH Industrial works with the specialized engineering teams of manufacturers to meet our customer's requirements and the highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Pneumatic Vibrators

Manufacturers

What are Pneumatic Vibrators?

Pneumatic vibrators are mechanical devices that generate vibrations through compressed air. These vibrations are instrumental in facilitating the flow of materials and preventing blockages in various industrial processes. With their ability to operate without electrical power, pneumatic vibrators are especially suitable for environments where electrical components may pose safety hazards or are not feasible.

Pneumatic vibrators operate on a simple principle. Compressed air is directed into the vibrator, causing an internal piston or turbine to oscillate. This oscillation generates vibrations, which are then transferred to the equipment or material being handled. The resulting vibrations help in dislodging materials, enhancing flow, and improving overall efficiency.

The Importance of Pneumatic Vibrators in Industrial Settings

In industrial settings, especially where materials need to be conveyed, transported, or processed, the proper flow of these materials is critical. Pneumatic vibrators play a crucial role in ensuring the smooth movement of materials, preventing clogs and jams, and ultimately reducing downtime and maintenance costs.

Types of Pneumatic Vibrators

Turbine Vibrators

Turbine vibrators are a popular choice for applications requiring high-frequency vibrations. They are particularly effective in dislodging fine, powdery materials and can be used in hoppers, bins, and chutes.

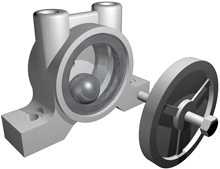

Ball Vibrators

Ball vibrators, as the name suggests, use a ball inside the vibrator housing to create vibrations. They are versatile and suitable for various materials and applications, including compacting concrete and improving material flow in hoppers.

Piston Vibrators

Piston vibrators are known for their powerful vibrations and are often used in applications where a higher force is required. These vibrators find applications in dislodging stubborn materials and facilitating material flow.

KA Internal Concrete Vibrators

KA internal concrete vibrators are specifically designed for concrete compaction. They ensure uniform distribution of concrete, eliminating air pockets and enhancing the structural integrity of concrete elements.

Big Buster Vibrators

Big Buster vibrators are heavy-duty devices used to facilitate the flow of stubborn materials in large containers or pipelines. Their forceful vibrations effectively eliminate blockages, reducing the need for manual intervention.

Advantages of Pneumatic Vibrators

Versatility in Challenging Environments

Pneumatic vibrators are engineered to withstand extreme conditions, making them ideal for use in environments with high temperatures, low temperatures, and caustic substances. Their robust construction ensures long-lasting performance even in harsh settings, contributing to increased productivity and reduced downtime.

Sanitary Working Conditions

In industries like food, pharmaceuticals, and chemicals, maintaining sanitary conditions is crucial to ensure product quality and safety. Pneumatic vibrators are designed with hygiene in mind, and their application in such settings helps prevent contamination and adheres to strict industry regulations.

Energy Efficiency

Compressed air, the driving force behind pneumatic vibrators, is an energy-efficient power source. Compared to electric vibrators, these devices offer cost savings and a reduced environmental footprint, making them a sustainable choice for businesses.

Conclusion

Pneumatic vibrators play a crucial role in enhancing industrial efficiency, especially in challenging environmental conditions. Their ability to operate in high-temperature, low-temperature, and caustic environments, along with their contribution to maintaining sanitary working conditions, makes them indispensable in food, chemical, pharmaceutical, and other industries. By offering a wide range of vibrators, each optimized for specific applications, businesses can find tailored solutions to optimize material flow and streamline their production processes.