Shrink Discs

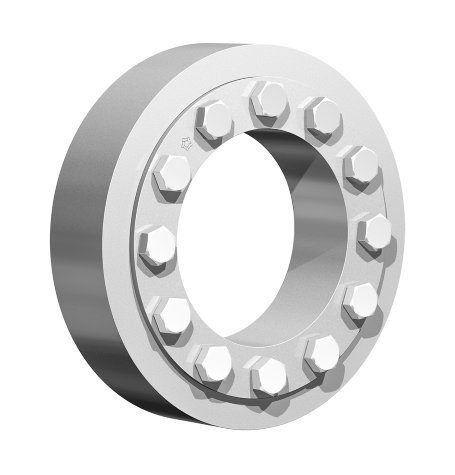

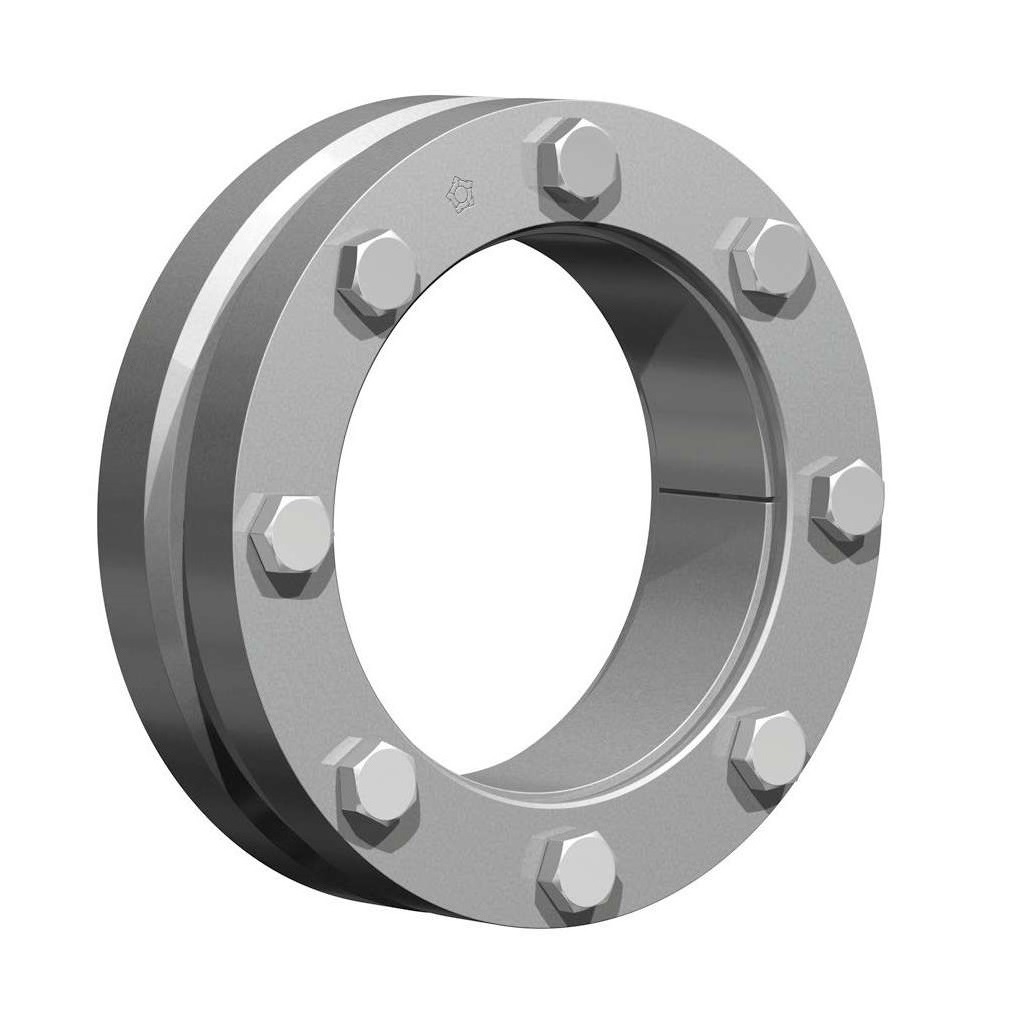

Shrink Discs are flange-shaped, friction-locked shaft-hub connections free of wear and maintenance. In the case of a shrink disc, the torque is transmitted in a force-locking manner at the joining surface between the shaft and hub without an intermediate element. Shrink discs are available in two- and three-part designs and stainless-steel material.

We offer a wide range of shrink discs ideal for thin-walled hubs and shafts, smaller shaft diameters, and high torques, the highest and lower transmission values, extreme loads, and others.

HVH Industrial works with manufacturers' specialized engineering teams to meet our customers' requirements and highest quality standards.

If you have any questions, write us via live chat, (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Shrink Discs

Manufacturers

Keyless locking devices are an essential part of modern machinery and equipment. They are used to provide a strong and secure connection between two components while also allowing for easy disassembly and maintenance. Shrink discs are a type of keyless locking device that has become increasingly popular due to their ease of use and reliability. In this article, we will explore what shrink discs are, how they work, and their advantages over other types of keyless locking devices.

What are Shrink Discs?

A shrink disc is a type of keyless locking device that uses friction to create a strong and secure connection between two components. It consists of a tapered ring with a series of screws or bolts that are used to tighten the disc onto a shaft. The tapered ring is then heated using an induction heater, causing it to expand and create a tight fit between the shaft and the disc.

Shrink discs work by using friction to connect two components tightly. The disc is designed to fit tightly around a shaft, with a series of screws or bolts used to tighten it in place. The tapered ring is then heated, causing it to expand and create a tight fit between the disc and the shaft. This creates a secure connection that can withstand high torque and axial loads.

Shrink discs are often used in high-torque applications where traditional keys or other locking devices may fail due to the high stresses involved. They are also popular in situations where components need to be easily removable for maintenance or repair, as the shrink disc can be easily heated again to expand and remove it.

Types of Shrink Discs

There are several types of shrink discs available, each designed to meet specific application requirements. These include:

Standard Shrink Discs

Standard shrink discs are the most common type of shrink disc and are suitable for a wide range of applications. They are available in a variety of sizes and can be used with most standard shaft sizes.

Self-Centering Shrink Discs

Self-centering shrink discs are designed to center themselves on the shaft, making installation quick and easy. They are ideal for applications where precise alignment is critical.

Heavy-Duty Shrink Discs

Heavy-duty shrink discs are designed to withstand higher torque and axial loads than standard shrink discs. They are ideal for use in heavy machinery and equipment.

Stainless Steel Shrink Discs

Stainless steel shrink discs are designed for use in harsh environments where corrosion resistance is critical. They are ideal for use in the marine, oil and gas, and chemical industries.

Advantages of Shrink Discs

Shrink discs offer several advantages over other types of keyless locking devices. These include:

Easy installation

Shrink discs are easy to install and require minimal tools or equipment. This makes them an ideal choice for applications where time and resources are limited.

High torque and axial load capacity

Shrink discs can withstand high torque and axial loads, making them suitable for use in heavy machinery and equipment.

Precise positioning

Shrink discs allow for precise positioning of components, making them ideal for applications where accurate alignment is critical.

Easy disassembly

Shrink discs are easy to disassemble and do not require specialized tools or equipment. This makes them an ideal choice for applications where regular maintenance is required.

Design Considerations

When designing a shrink disc connection, there are several factors that must be considered. The first is the torque load that will be transmitted through the connection. This will determine the size of the shrink disc required, as well as the number of bolts needed to secure it.

The second factor to consider is the surface finish of the hub or shaft. Shrink discs require a smooth surface finish to create a proper frictional connection, so any roughness or imperfections on the surface can negatively impact the connection.

Finally, it is important to consider the environment in which the connection will be used. Shrink discs are not suitable for high-temperature or corrosive environments, so alternative methods may be needed in these situations.

Conclusion

Shrink discs are an essential part of modern machinery and equipment. They offer several advantages over other types of keyless locking devices, including easy installation, high torque and axial load capacity, precise positioning, and easy disassembly. With several types of shrink discs available, there is a solution to meet every application requirement.