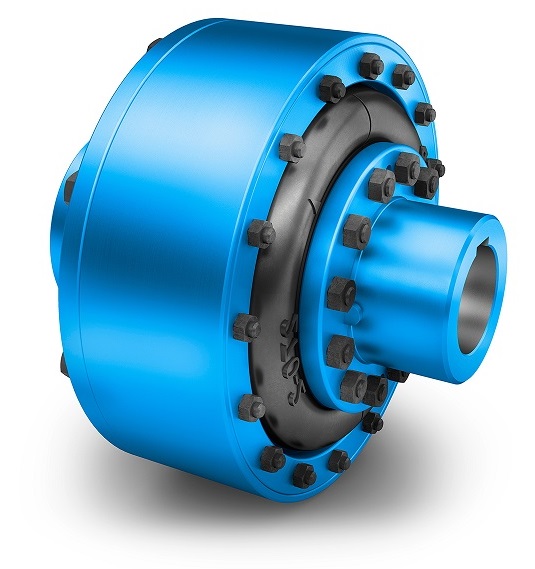

Tire Couplings

Tire Couplings are torsionally soft flexible couplings that provide an optimum torque transmission and allow compensation for large quantities of shock-loading backlash and parallel and axial misalignments. These non-lubricated couplings consist of two hubs made of cast iron or steel with two halves joined by rubber tires. We offer a wide range of tire couplings such as Dura-Flex, Rubber Tire, Flexible Ring Couplings, and more.

The Tire Couplings can be widely used for piston pumps, compressors, reversing rolling mills, internal combustion engines, crushers, mixers, wastewater purification plants, etc.

HVH Industrial works with manufacturers' specialized engineering teams to meet our customers' requirements and highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Tire Couplings

Manufacturers

In the dynamic world of machinery and engineering, the efficient transmission of torque and the ability to withstand various stresses are crucial factors. This is where tire couplings come into play. These versatile components offer a unique combination of flexibility and strength, making them an indispensable part of numerous industrial applications.

What Are Tire Couplings?

Tire couplings are mechanical devices designed to connect two shafts while allowing for angular and parallel misalignments. They are torsionally soft, which means they possess a certain degree of flexibility to absorb shocks and vibrations, ensuring smooth torque transmission.

Construction of Tire Couplings

Tire couplings consist of two hubs made from materials such as cast iron or steel. These hubs are joined by rubber tires, which are the defining elements of this coupling type. The rubber tires provide the necessary flexibility and damping effect, enabling the coupling to accommodate misalignments and shocks.

Functionality and Benefits

The primary function of tire couplings is to transmit torque from one shaft to another while compensating for misalignments and absorbing shocks. This functionality ensures that machinery operates with reduced wear and tear, prolonging the lifespan of both the coupling and the connected components. The inherent dampening properties of rubber tires contribute to noise reduction and vibration isolation.

Types of Tire Couplings

Dura-Flex Couplings

Dura-Flex Tire Couplings are the outcome of meticulous engineering, utilizing finite element analysis to achieve unparalleled flex life. These couplings are engineered to withstand the rigors of industrial environments while providing smooth and efficient power transmission.

Rubber Tire Couplings

ELPEX-B Rubber Tire Couplings stand out for their backlash-free design, making them ideal for machines with non-uniform torque characteristics. These couplings transmit torques through a flexible tire reinforced with a cord ply, ensuring efficient power transmission without circumferential backlash.

Flexible Ring Couplings

ELPEX Ring/Tire Couplings, renowned for their exceptional flexibility and damping properties, excel in connecting machines with non-uniform torque characteristics. The unique transmission characteristics of these couplings are attributed to their flexible rings, crafted from a blend of natural rubber and a multi-ply fabric lining.

Applications of Tire Couplings

The versatility of tire couplings lends them to a wide array of industries:

Piston Pumps: Smooth torque transmission in pumping systems.

Compressors: Vibration reduction in air compression units.

Rolling Mills: Absorption of shocks in metal processing.

Internal Combustion Engines: Minimized stress in engine-driven machinery.

Crushers: Protection from impact loads in crushing equipment.

Mixers: Efficient power transfer in mixing operations.

Wastewater Purification Plants: Reliable performance in water treatment systems.

Advantages of Tire Couplings

Tire couplings offer a range of advantages that make them a popular choice in industrial applications. Some key benefits include:

Shock Absorption: The rubber tires absorb shocks and vibrations, protecting machinery from sudden jolts.

Misalignment Compensation: Tire couplings can accommodate parallel, axial, and angular misalignments, minimizing wear and tear.

Maintenance-Free: Non-lubricated design reduces the need for constant maintenance.

Cost-Effective: Tire couplings' longevity and low maintenance contribute to cost savings over time.

Conclusion

Tire couplings emerge as important components that ensure seamless torque transmission, shock-loading compensation, and misalignment tolerance of industrial machinery. Their versatility and reliability make them a cornerstone of various applications, from automotive systems to power generation plants. By absorbing shocks and accommodating misalignments, tire couplings contribute to the efficiency, durability, and smooth operation of machinery across diverse industries.