HVH Industrial Solutions is an authorized distributor of Foot Master

Foot Master's multi-functional casters provide ease of movement and level settings, for a wide variety of machines, equipment, and workstations.

The shock-absorbing caster is the first product in the world to use a special rubber spring. It absorbs subtle vibrations with ease and can endure high temperatures.

AGV casters with offset optimization, special rubber spring, tilting feature, and dual swivel structure are used for cutting-edge robot industries serving as a key part of future industries.

At HVH, we work closely with the Foot Master engineering team to provide superior customer service and engineering support.

Foot Master Literature:

If you have any questions, write us via live chat (one of our team members will answer your questions), call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Foot Master Products

About Foot Master

G-DOK Industries Co., Ltd., a total caster engineering company, has been revolutionizing the caster industry since its establishment in 1989 in South Korea. With its renowned brand of Foot Master and Casters & Wheels G-Dok Industries, the company has emerged as a leader in caster innovation, catering to global markets

Foot Master has always prioritized innovation and cutting-edge technology. By staying ahead of market trends and investing in research and development, the company has been able to introduce advanced caster designs that offer superior performance, durability, and maneuverability. This commitment to innovation has earned Foot Master a reputation for producing top-of-the-line casters that can withstand demanding environments and heavy loads.

Foot Master Products

Leveling Casters

Leveling casters are designed to provide stability and adjustability to equipment. They feature a leveling mechanism that allows the user to adjust the height and level of the equipment. These casters are particularly useful for equipment placed on uneven surfaces or for applications where precise leveling is required.

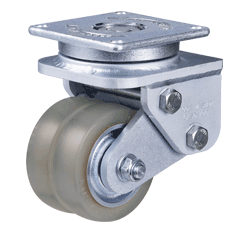

Shock Absorbing Casters

Shock-absorbing casters are designed to reduce vibrations and impacts during equipment movement. They feature specialized materials and mechanisms that absorb shocks and provide a smoother rolling experience. These casters are commonly used in applications where delicate equipment or materials need protection from vibrations, such as medical devices or electronic equipment.

Compact Casters

Compact casters, as the name suggests, are designed to provide mobility while occupying minimal space. They are commonly used in compact or space-constrained applications where a smaller caster footprint is required. These casters are often used in furniture, cabinets, and other applications where space optimization is essential.

AGV Casters

AGV casters, also known as Automatic Guided Vehicle casters, are specifically designed for use in automated material handling systems. These casters enable smooth and precise movement of automated guided vehicles, enhancing their efficiency and productivity. AGV casters are equipped with advanced features like swivel locks and precision bearings to ensure accurate navigation and control.

Heavy Duty Casters

Heavy-duty casters are designed to handle exceptionally heavy loads in demanding environments. These casters are commonly used in industries such as manufacturing, construction, and transportation, where the equipment and machinery require reliable and robust mobility solutions. Heavy-duty casters provide exceptional load-bearing capacity, durability, and resistance to impact and wear.

Stainless Steel Casters

Stainless steel casters are specifically designed for applications that require resistance to corrosion, chemicals, and moisture. These casters are widely used in industries such as food processing, pharmaceuticals, and healthcare, where strict hygiene standards and environmental factors come into play. Stainless steel casters offer exceptional durability, cleanliness, and resistance to rust and contamination.

Benefits of Foot Master Casters

Enhanced Stability and Load Capacity

Foot Master casters offer excellent stability, allowing equipment to be easily moved and positioned without the risk of tipping or imbalance. They are designed to handle heavy loads and distribute weight evenly, ensuring optimal load capacity.

Improved Shock Absorption

The shock-absorbing feature of Foot Master casters reduces vibrations and impact, protecting equipment and sensitive materials from damage. This feature is particularly beneficial in applications where equipment needs to be transported over uneven or rough surfaces.

Space-Saving Design

Compact casters provide the advantage of mobility without compromising space. They are ideal for applications where limited space is available, allowing equipment or furniture to be easily moved without taking up excess room.

Factors to Consider When Choosing Foot Master

When selecting the right cater wheels for your specific requirements, keep the following factors in mind:

Load Capacity: Consider the weight of the object that needs to be moved and choose cater wheels that can handle the load without compromising performance.

Surface Compatibility: Different caster wheels are designed for specific surfaces, such as concrete, wood, or carpet. Ensure that the cater wheels you choose are suitable for the surface you'll be operating on.

Environment: If your application involves extreme temperatures, chemicals, or exposure to outdoor elements, select cater wheels that are resistant to such conditions.

Maintenance and Care for Casters and Wheels

To ensure optimal performance and longevity of casters and wheels, follow these maintenance tips:

Regular cleaning and lubrication: Clean casters regularly to remove dirt, debris, or buildup that may hinder smooth movement. Apply appropriate lubricants to keep the wheels rolling smoothly.

Inspection for wear and damage: Periodically inspect casters for signs of wear, such as flat spots on wheels or damaged mounting plates. Replace any worn-out or damaged components promptly.

Replacement of worn-out components: When casters exhibit significant wear or damage, replace them to maintain the desired level of performance and safety.

Proper storage and handling: Store casters in a clean and dry environment when not in use. Handle them with care to avoid unnecessary stress or damage.

Casters and wheels are integral to the efficient and smooth functioning of various industries. By understanding the different types of casters, factors to consider when choosing them, their applications, benefits, and maintenance requirements, you can make informed decisions when selecting and using casters. Remember to choose a reputable caster supplier to ensure the quality and reliability of the products you purchase.