The Difference Between Keyed and Keyless Connections

There are two different types of connections between a shaft and a hub. This article will discuss the differences between the keyed shaft and keyless connections and their advantages/disadvantages.

Keyed Shaft Connections

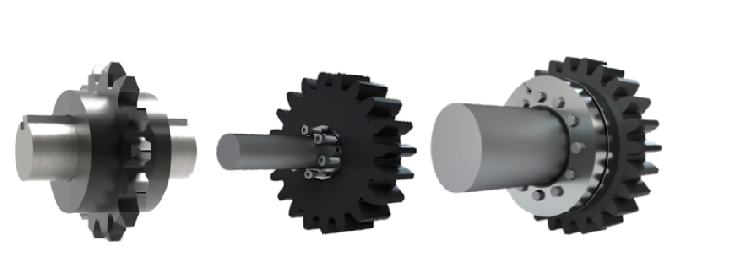

A key is usually a piece of metal used to connect a shaft, and a hub is mounted over the shaft and acts as a temporary joint. The key is placed between the post and the hub in the hole (keyway). For the key to connect between the shaft and the hub and function normally, both the shaft and rotating hub must have a suitable keyway and a keyseat. The keyway is a cut in the rotating hub, while the keyseat is a precut pocket in the shaft to fit in the key. The system together is called a keyed joint, as seen below. The keyed joint allows axial movement between the different parts.

Keyless Shaft Connection

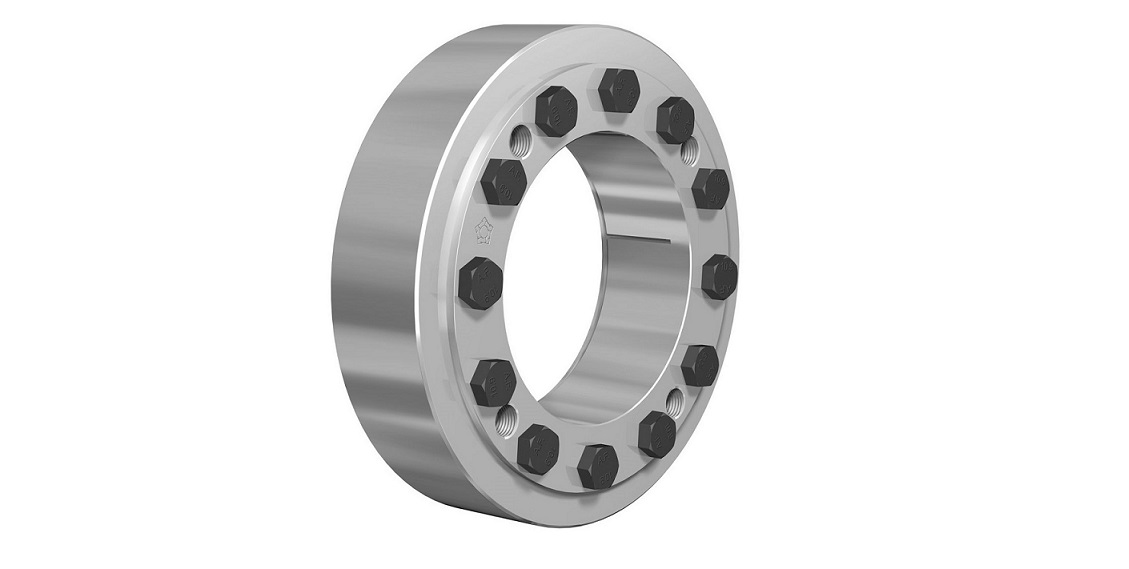

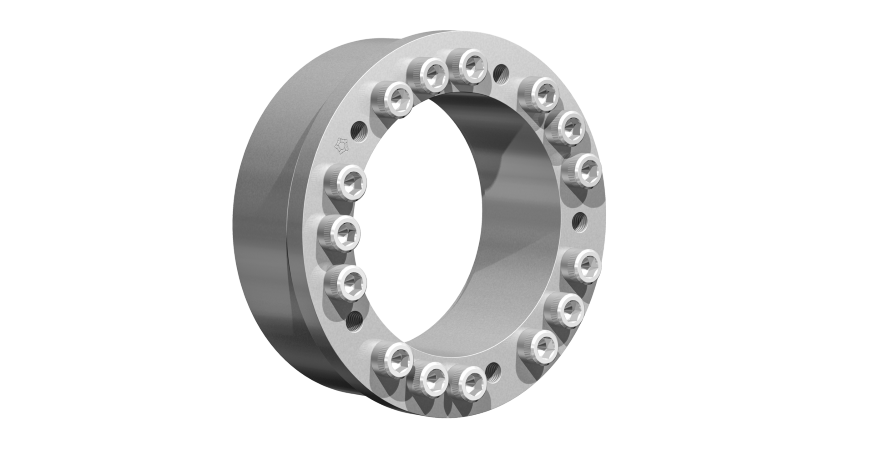

The keyless shaft connection, also known as a locking assembly, comprises a round bore that depends solely on the clamping force or set screw holding power to lock onto a round shaft. The locking assembly is installed in the hub and then mounted on the shaft. The locking assembly covers the entire circumference of the shaft and connects the shaft and the hub in a secure way. The keyless shaft connection consists of rings, bushes, and bolts. The rings and bush are joined together with the bolts, and the bolts are stiffened with a tightening torque that secures the shaft.

The keyless connections are divided into internal and external locking devices called shrink discs. A Shrink disc is a type of keyless connection that's flange-shaped and is more secure than typical shrink fits because, when locked, it creates an entirely backlash-free, frictionally engaged connection between the shaft and the hub.

Advantages of keyed connections over keyless connections:

-

A keyed connection allows for more tolerance between the shaft and hub, whereas in a keyless connection, the parts should be cleaned and machined to allow tolerances.

-

A keyed connection shows a clear visual of the locked shaft and hub, while in a keyless connection, the shaft and hub need to be inscribed with a timing mark.

-

A keyed connection is much cheaper than the keyless connection

-

Well-established standards ( ISO, ANSI, DIN, ANSI)

Advantages of keyless connections over keyed connections:

-

A keyless connection transmits more torque than a keyed connection and provides a more secure connection because of the increased shaft surface contact area.

-

In a keyed connection, looseness occurs between the shaft and key, which causes movement and friction, and fretting corrosion. The fretting corrosion can weld the shaft and connector together extremely hard to separate them and cause shaft failures. In a keyless connection, fretting corrosion rarely occurs, and separating the parts can be quickly done.

-

Installation is much easier when using a keyless connection, as the shaft position does not affect the motor, as the motor can slide in any position. While using a keyed connection, the keyways should be aligned to mount the reducer on the shaft.

-

Keyless connections can hold much higher axial loads.

You can easily find the appropriate connection method for your specific application based on the given information.

Check our article about keyless locking assemblies and their different applications to understand better what suits your project.

Feel free to Contact Us if you have any questions or need more information regarding the difference between keyed and keyless connections.

HVH Industrial Solutions is an authorized distributor of the following keyless locking device manufacturers: Ringfeder, Ringspann, and Rota Free / Compomac. We work closely with their engineering teams to provide superior customer service and support.