What are Two-Part and Three-Part Shrink Discs

A shrink disc, a type of keyless locking device, is crucial in securing hollow shafts or hubs to shafts with backlash-free precision. In this article, we will discuss two-part and three-part shrink discs, exploring their design and assembly processes.

What are Shrink Discs

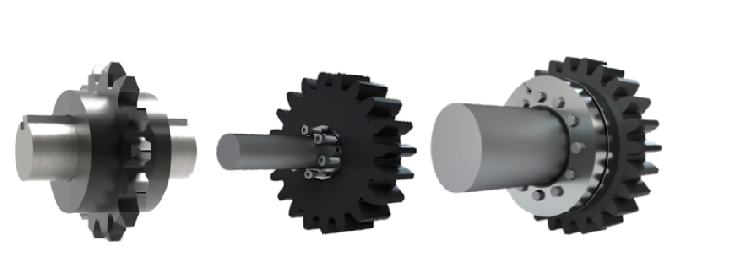

Shrink discs serve as external clamping connections designed for the secure and backlash-free fastening of hollow shafts or hubs to shafts. The mechanism involves tightening clamping screws, which pull conical surfaces together, generating radial forces. These forces, in turn, press the hollow shaft onto the shaft, enabling the frictional transmission of torques or axial forces from the hollow shaft to the shaft. The shrink disc itself does not play a direct role in transmitting torques or axial forces.

There are two primary types of shrink discs: the two-part and the three-part shrink discs, each offering unique features and advantages.

Two-Part Shrink Discs

Design

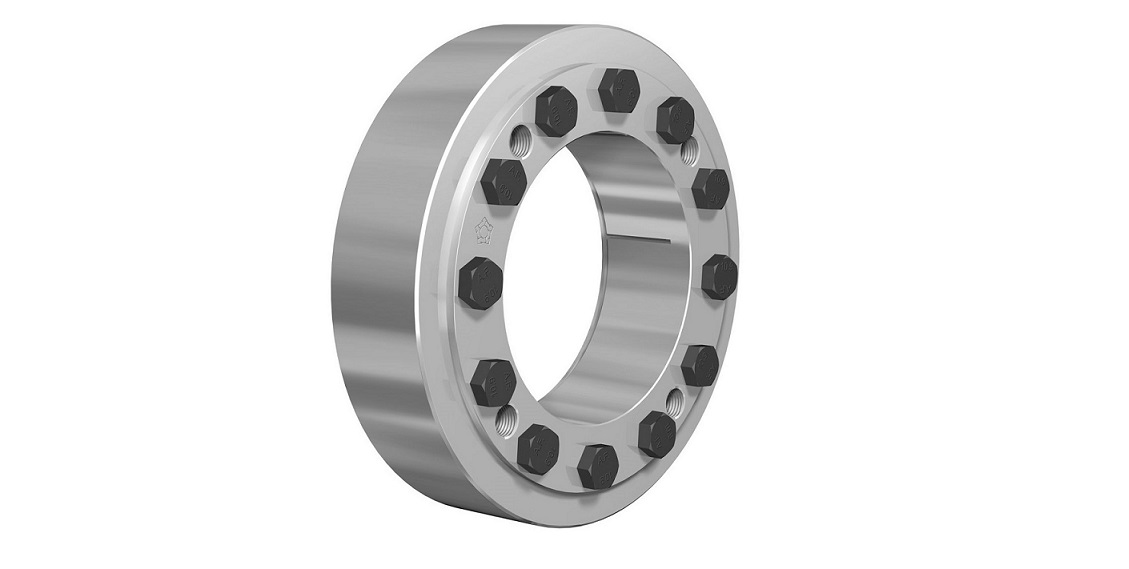

Two-part shrink discs consist of an outer stepped conical ring, an inner stepped conical bush, and clamping screws.

The stepped conical ring is pulled onto the stepped conical bush by tightening the clamping screws. A radial clamping force is generated by the conical surfaces. The force presses the hollow shaft onto the shaft, forming a frictional connection at the contact surfaces.

This connection allows the transmission of torque and axial force between the shaft and hollow shaft. The position of the conical bush relative to the hollow shaft stays constant during the clamping process. To release the connection, the clamping screws in the threaded bores for the jacking screws are tightened.

Distance-Controlled Assembly

A unique feature of two-part shrink discs is distance-controlled assembly. Uniform tightening of clamping screws ensures the correct positioning of components, guaranteeing the transmissible torques specified. It's crucial to note that proper lubrication is essential for a successful assembly process.

Characteristics

-

Easy and quick assembly without a torque wrench

-

Modern design with high power density

-

Distance-controlled assembly for guaranteed torque transmission

-

Enclosed design, impervious to dirt

-

True running even at high speeds

Three-Part Shrink Discs

Design

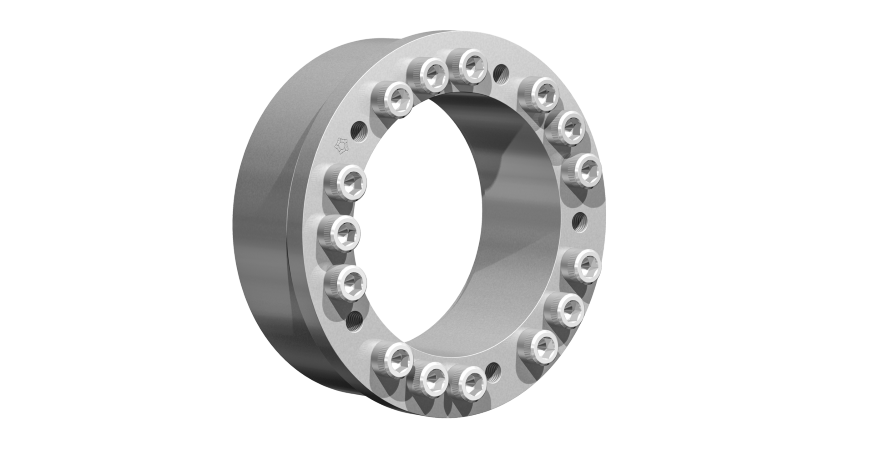

Three-part shrink discs consist of a threaded flange, a pressure flange, a slotted inner ring, and clamping screws. Similar to two-part discs, clamping screws play a central role in pulling components together during assembly.

The clamping screws tighten, bringing the threaded flange and pressure flange together over the inner ring. This action generates a radial clamping force, which depends on the friction coefficients at the screws and conical surfaces. The resulting force presses the hollow shaft onto the shaft, establishing a frictional connection at the contact surfaces between the two. This connection facilitates the transmission of torque and/or axial force between the shaft and the hollow shaft.

Throughout the clamping process, the position of the inner ring relative to the hollow shaft remains constant. Releasing the connection is a straightforward process achieved by simply loosening the clamping screws, thanks to the self-releasing cone angles.

Torque-controlled assembly

The clamping screws are tightened uniformly clockwise until the specified torque is reached. If there is insufficient or absent lubrication on the conical surfaces, which may occur during servicing, it leads to a decrease in the radial clamping force. As a consequence, the torques or axial forces specified in the tables can no longer be reliably transmitted. This situation is often overlooked because the specified tightening torque was achieved during assembly, and the assembly process is deemed finished.

Characteristics

-

Tightening of clamping screws with a torque wrench

-

Classical design

-

Torque-controlled assembly

-

Easy disassembly without jacking screws

Conclusion

Shrink discs find applications in various machinery, such as fastening machine shafts to gearboxes with hollow shafts. Their versatility and features like distance-controlled and torque-controlled assembly make them integral components in ensuring efficient and reliable mechanical connections. Whether opting for the two-part shrink discs or the three-part discs, these components play a crucial role in enhancing the performance of machinery across industries.

HVH Industrial Solutions is an authorized distributor of Ringfeder, Climax Metal Products, Rexnord Tollok, Lovejoy, and Ringspann, and we offer a wide range of their products. We work closely with their engineering team to provide superior customer service and engineering support.

If you have any questions, write to us via live chat or call or send us a quote request. The HVH team is always ready to help you.