Combined Gear Units

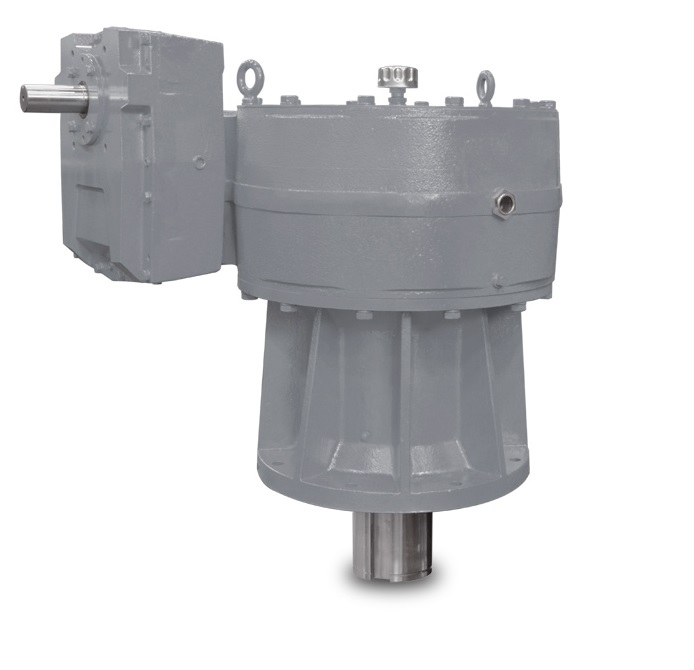

We offer a wide range of Gear Units combined with helical & helical bevel gear reducers and planetary gear reducers, as well as Single Worm, Double Worm, and Triple Worm Gear Reducers. Used in conveyors, mixers, rolling mills, material and chemical processes, pollution control, and many other applications they provide smooth and quiet operation, economic and efficient mixing at lower speeds, and long service life.

HVH Industrial works with the specialized engineering teams of manufacturers to meet our customer's requirements and the highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Combined Gear Units

Manufacturers

In today's fast-paced world, machinery and industrial equipment have become vital parts of our lives. Every day, we rely on machines to do the heavy lifting, and at the heart of every machine lies a crucial component known as a gear reducer. A gear reducer is an essential component in any machine or industrial equipment that requires torque to function efficiently.

Combined Gear Units

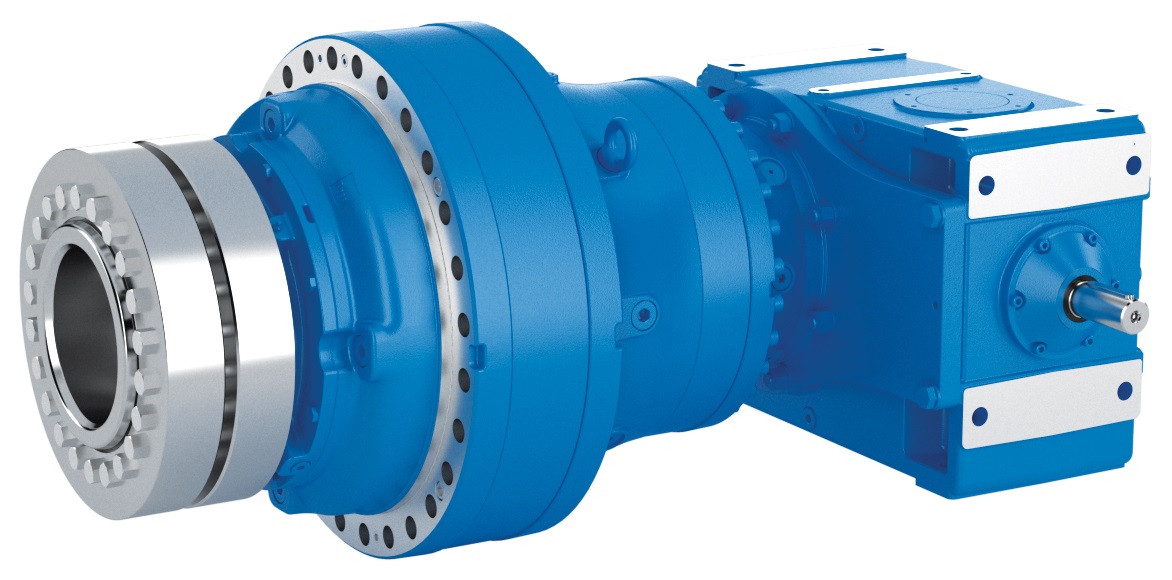

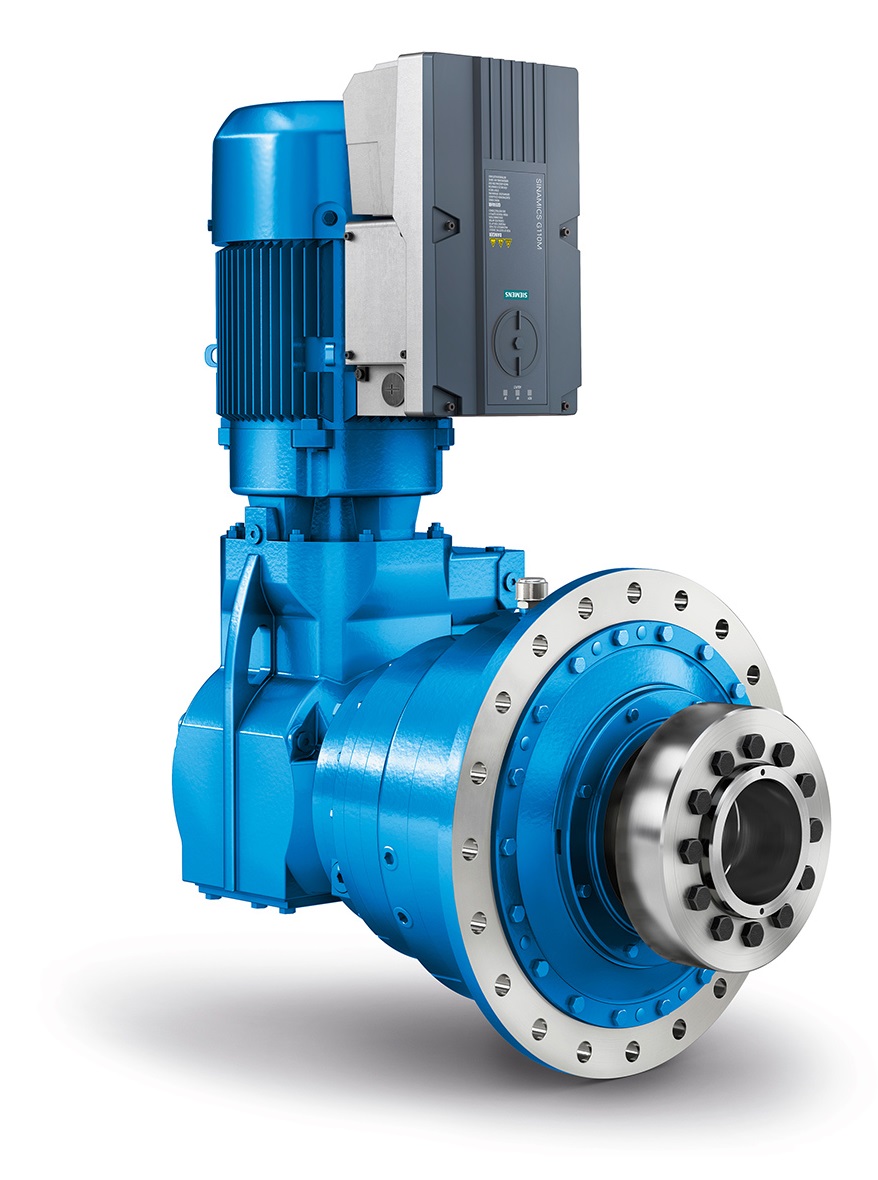

Combined gear units are a type of gearbox that combines two or more types of gears to achieve specific performance characteristics, such as speed, torque, or power transmission. They are made up of a combination of gears, such as bevel, helical, worm, or planetary gears, arranged in a specific sequence and ratio to produce the desired output. This configuration allows for a higher gear ratio, which means that the output speed can be reduced while the output torque is increased. Combined gear units can be used in various types of machinery, including conveyors, cranes, and mixers.

How do Combined Gear Units Work?

Combined gear units work by transferring power from a motor to an output device. The input shaft is connected to the motor, which rotates the gears inside the housing. As the gears mesh with each other, they transfer the rotational energy to the output shaft. The gear ratio of the unit determines the speed and torque of the output shaft. A higher gear ratio results in a lower output speed and higher output torque, while a lower gear ratio produces a higher output speed and lower output torque.

Types of Combined Gear Units

At HVH Industrial Solutions, we offer a wide range of combined gear units such as single-worm gear reducers, double-worm gear reducers, triple-worm gear reducers, Delroyd worm gear mixer units, and many more.

Single-worm gear reducers are designed to reduce the speed of an input shaft by a single-gear ratio. This type of reducer is ideal for applications that require a single-speed reduction. Single worm gear reducers are typically used in applications that require low power, such as conveyor systems.

Double worm gear reducers are designed to reduce the speed of an input shaft by two gear ratios. A double worm gear reducer is ideal for applications that require two stages of speed reduction, typically used in applications that require high torque, such as winches.

Triple worm gear reducers are designed to reduce the speed of an input shaft by three gear ratios. A triple worm gear reducer is ideal for applications that require three stages of speed reduction, especially applications that require very high torque, such as industrial machinery.

The HP series of Worm Gear Reducers for mixers and agitators are engineered to withstand up to 300% momentary peak overloads. They are used in material and chemical processes, pollution control, and cement/aggregate. The dry well construction of the worm gear unit helps protect against lubricants leakage. They provide economic and efficient mixing at lower speeds and feature two modes of reduction. Single reduction Delroyd worm gear sets can provide reductions of 5:1 through 70:1, for output speeds down to 25 rpm. Double reduction Delroyd helical-worm gear reducers can go from a 15:1 to 350:1 ratio to provide outputs as low as 5 rpm

In conclusion, combined gear units are mechanical devices that combine two or more different gear types in one unit and are designed to provide more power, speed, and torque, making them a popular choice in various industries, including manufacturing, mining, and agriculture. These units are often used in heavy-duty applications, where high-power transmission is required.