Gear Reducers

A gear reducer also called a speed reducer or gearbox is a mechanical transmission device that connects a motor to a driven load. They are used to reduce the speed with which power is transmitted.

Gear reducers are used to operate all types of industrial and household machines, which need to reduce the speed of an electric motor safely and efficiently.

A wide range of speed reducers is available such as right angle, inline, parallel shaft, servo gear reducers, and more. We also offer custom-designed speed reducers appropriate to your application.

HVH Industrial works with the specialized engineering teams of manufacturers to meet our customer's requirements and the highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Gear Reducers

Manufacturers

A gear reducer is a mechanical transmission device that reduces the output rotational speed of the motor and increases the torque created by the motor. Multiplying the torque produced by the motor leads to the increase of serviceable power to the machine connected. Gear reducers are used to improve the efficiency of any operation. Any device consisting of gears used to connect a machine to a motor is called a gearbox. A gear reducer can also be called a gearbox, but not all gearboxes can be called gear reducers. A basic gear reducer usually consists of one large gear and another small gear placed together and both gears turning, as shown in the figure below.

This basic form of speed reducer is known as a single-gear reducer. Each turn in the big gear causes two turns for the small one, which leads to an increase in speed and loss of torque. Gear reduction occurs at preset ratios that meet the characteristics of the input and output gears. The speed reduction takes place by changing the ratio of the moving gears. For example, a gear that makes two rotations to turn a larger gear once has a ratio of 2:1, which means that the output speed has been cut in half.

Types of Gear Reducers

There are many different sets of gear reducers, depending on requirements related to cost, operational factors, geometry, noise, vibration, thermal environments, and load-bearing capability.

Helical Gear Reducers

A helical gear transmits torque between perpendicular or parallel input and output shafts. It contains angled gear teeth that gradually engage; input and output teeth are fully engaged as the gear rotates. As more teeth share the load at a specific time, a helical gear reducer has a big load-carrying capacity, which results in lower stress and reduced wear on gears. Also, the gradual engagement of the teeth leads to a quieter and smoother operation than other types of gear reducers. The main disadvantage of helical gear reducers is the high maintenance cost because of the complex finishing.

Helical Gear Reducer by SITI

Worm Gear Reducers

A worm gear reducer transmits rotations at a right angle, the input shaft being at 90⁰ to the output shaft, and is one of the least expensive and most compact gear reducers. It consists of an input gear(screw, worm) and an output worm gear. The main disadvantage of worm gear reducers is that they are less efficient than other gears because the gears experience sliding. Sliding in many cases causes friction and high operating temperatures.

Worm Gear Reducer by Motovario

Bevel Gear Reducers

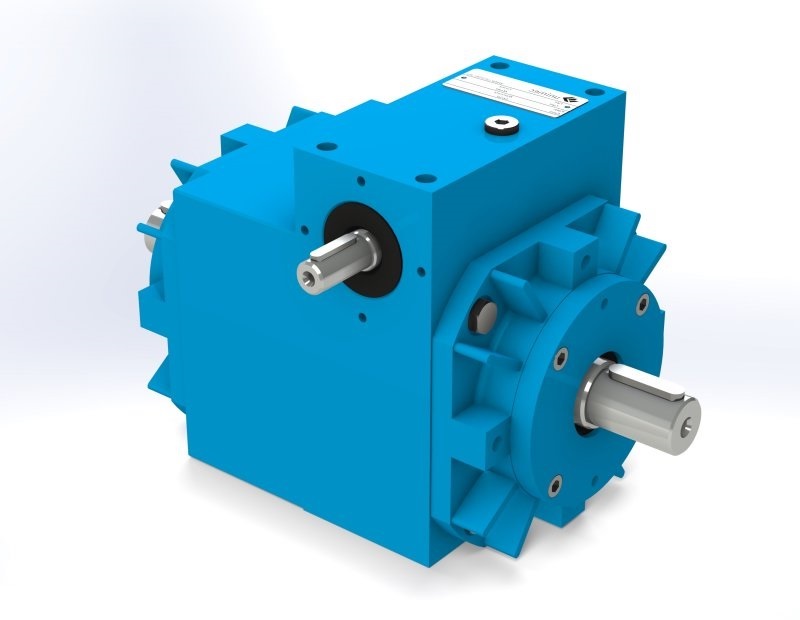

A bevel gear reducer is usually a cone-shaped gear that is configured at right angles and is used when the angle of the input shaft needs to be changed to accommodate the output shaft. A bevel gear reducer is suitable for applications that require a right-angle reducer with a low ratio. It is compact and can handle high power. A bevel gear is perfect for operations that require high torque.

Bevel Gear Reducer by SITI

Planetary Gear Reducers

A planetary gear reducer requires the motor and the driven device to be co-axial with each other. Planetary gearboxes are a type of gearbox where both input and output have the same center of rotation. This means that the center of the input gear revolves around the center of the output gear, and the input and output shafts are aligned. Planetary gears are suitable for significant torque or impact-loading applications because multiple gear teeth are engaged at once. Planetary gear reducers are compact, highly efficient, and have a long service life. The main disadvantage of planetary gear reducers is that they are more expensive than other types of gear because of their complex design.

Planetary gear reducer by Rossi

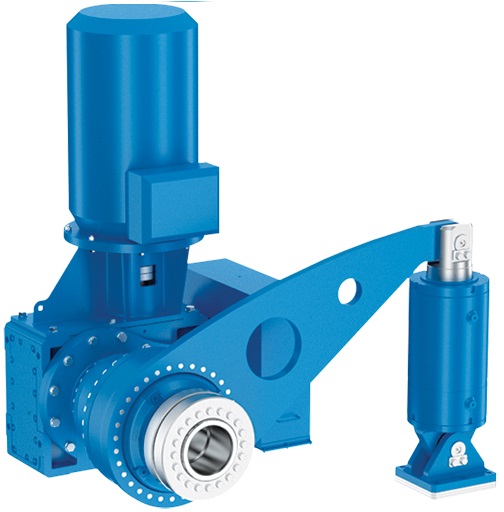

Shaft Mounted Gear Reducer

A shaft-mounted gear reducer is directly attached to the shaft of the driven device and includes a torque arm that anchors the reducer and maintains the proper belt tension. Shaft-mounted gear reducers are mainly used in elevators, crushers, conveyors, and mixers. The main advantages of a shaft-mounted gear reducer are that it is easy to install and the ability to prevent rotation in one direction.

Shaft Mounted-Gear Reducer by WorldWide Electric

Servo Gear Reducers

Servo gear reducers are maximum precision and dynamic products, combined with exceptional torque density and low torsional backlash, used in mechanical and mechatronic drives. These servo gearboxes develop complete, single-supplier solutions for driving any axis. They are found in the most diverse industries and applications due to their torque, speed, torsional backlash, rigidity, and ratio.

Servo Gear Reducer by Wittenstein

We offer a wide range of speed reducers such as worm, planetary, helical & bevel, servo, shaft mounted, right angle, and more. We also offer custom-designed speed reducers appropriate to your application.