Electric Motors

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Electrical motors can be powered by direct current (DC) sources, such as batteries and thermocouples, or by alternating current (AC) sources, such as electrical generators, inverters, power grids, etc.

Electric motors are generally designed for continuous rotation or linear movement over an essential distance compared to their size.

HVH Industrial works with manufacturers' specialized engineering teams to meet our customers' requirements and highest quality standards.

If you have any questions write us via live chat, (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Manufacturers

What are Electric Motors

Electric motors are the workhorse of the transmission industry, and that's a fact. It converts the energy received from electricity into rotational motion for use in homes, industries, and just about anywhere. All motors share specific characteristics, which must be identified when specifying them.

There are two main classes of electric motors: those that run on alternating current, called AC, and those that run on direct current, or DC. Types of alternating current include single-phase and three-phase, also called multi-phase. DC types include a permanent magnet, shunt wound, series wound, and compound wound. Other designs include servo, step motors, etc.

Working principle of electric motors

The electric motor works on the principle of electromagnetic Induction - the physical process of generating an electric current in a closed circuit, subject to a change in the magnetic flux moving through it.

According to this principle, the first electric motor was created in 1821 by the British scientist Michael Faraday. It was a loose steel wire immersed in a vat of mercury, where an eternal magnet was installed in the middle. Under the influence of electrical action on the wire, the latter formed a cyclic magnetic field around itself, making it rotate around the magnet.

Later, the principle of operation of an electric motor (electromagnetism) was brought to mind by the Russian scientist B. S. Jacobi. He was the first in 1834 to invent a technical device to create a circular rotation, which gave rise to mechanical devices set in motion. By developing this idea, Jacobi increased the power of his first prototype electric motor from 15 watts to 550 watts.

In 1839, the electric motor of this genius was able to develop one horsepower, which made it possible to move a boat weighing about a ton along the river against the current.

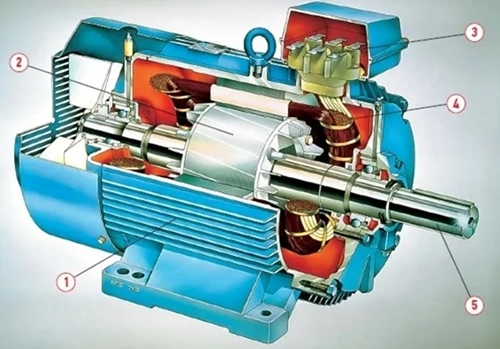

What it consists of The main parts

The design of any electric motor is based on the presence of two essential elements - the fixed part "stator" ("inductor" for DC motors) and the moving part "rotor" ("armature" for DC machines). A rotating electromagnetic field is generated under an electric current on the stator windings. It rotates in a specific direction under the influence of the rotor winding, thereby causing an induction current. Ampere's law explains this process: an electromotive force acts on a live conductor embedded in an electromagnetic field zone. Electric motors differ in the rotor (armature) speed parameter, which depends on the number of pairs of magnetic poles and the frequency of the primary supply voltage.

You can check the image below to understand which part is where visually.

1. Stator 2. Rotor 3. Terminal box 4. Stator winding 5. Shaft

The other parts we didn't mention are the terminal box, stator winding, and shaft. The terminal box is a protective device for an electric motor. The stator winding consists of three single coils stacked at 120 degrees relative to each other. The shaft converts energy from the motor into the end-use application. It is an essential and central part of any electric motor.

Types

An Electric Motor is an electric device that converts electrical energy into mechanical energy. It is designed for permanent rotation or linear movement over a substantial distance, depending on the size. They operate in the following principle: a current-carrying conductor produces an electromagnetic field that may be tightened or warded by another electromagnetic field. There is a wide range of electric motors worldwide, but their difference is the method used to create the magnetic field and control the current.

Electric motors are more efficient in the industry than any other electrical machine. They are lighter, smaller, mechanically more straightforward and cheaper to build, more durable and reliable, provide instant and resistant torque at any speed, and do not emit carbon into the atmosphere. Electric motors are very convenient products in various inside and outside applications. They are available in National Electrical Manufacturers Association (NEMA) and International Electrotechnical Commission (IEC) versions, which are separated into the following types:

AC Motors

AC motors are powered by alternating current sources, such as power grids, inverters, or electric generators. They are available in single-phase and three-phase versions. Single-phase means that only 1 V waveforms is applied to the motor. Single-phase motors supply 115 V or 230 V power, generally used in homes and small factories. Three-phase motors supply 460 V, 575 V, or higher voltages and are ideal for heavy-duty equipment. AC motors consist of two main parts: the rotor and the stator, where the stator creates a magnetic field and causes the rotor to rotate.

Synchronous Motors

A synchronous motor is an AC motor whose rotation is synchronized with the electric frequency of the alternating current. As the name implies, this motor rotates at a constant (synchronous) speed. Synchronous motors are widely used in the applications that require high precision and constant speed, such as paper and textile fiber industries. They come in single-phase and three-phase versions. Single-phase synchronous motors are suitable for precise timing applications, like clocks or tape players. Three-phase synchronous motors meet in industries with a large, reasonably steady mechanical load.

Induction Motors

An Induction Motor / asynchronous motor is the simplest and the most robust structured AC motor in the motors world. It works by induction principle, where an electromagnetic field is induced into the rotor when the stator's rotating magnetic field carves the fixed rotor. We call the motors asynchronous because they operate with less speed than their synchronous speed. That is the rotational speed of the stator's magnetic field. Induction motors are available in single-phase, three-phase, and split-phase versions.

DC Motors

DC motors are powered by direct current sources, as the name implies. Direct current does not change direction and always moves in the same direction. An excellent example of DC is a battery with two plates: anode (+) and cathode (-), separated by an electrolyte. The electrolyte creates a chemical reaction making the electrons move from the anode to the cathode inside the battery. Although they are more complex and require more maintenance than AC motors, DC motors can operate at adjustable speeds when connected to relatively simple controllers.

Servo Motors

A servo motor is a particular motor class with low inertias and high response. It consists of a motor coupled to a sensor for position feedback. The motor allows the motor to accelerate from zero to full speed in milliseconds. They are designed for the most challenging environments, operating under extreme temperature conditions, for rapid-reversing and precision-positioning applications, such as inspection equipment, machine tools, packaging machines, and pick-and-place applications.

Electric motor uses

Today, in almost any mechanical device, a combination of kinetic and potential energy is used - mechanical power is the source of the driving force responsible for the entire system's operation. With the discovery of electricity, it became possible to convert mechanical energy from electrical energy using an electromechanical machine - an electric motor. Thus, electric motors are so widespread that we can say that electric motors are everywhere.

Now let's talk about the specific use of specific electric motors.

AC motor is used in crushers, pumps, woodworking machines, etc. This motor's power ranges from 0.2 to 200 and higher kilowatts. DC motors are used in electric mopeds, vehicles, toys, and construction machines. Now let's check where we use asynchronous and synchronous motors. Asynchronous motors are used in many branches of technology, in air conditioners, washing machines, etc. Also, these motors are used in industry, for example, in metalworking or weaving. For example, synchronous motors are used in pumping stations.

Inventor of the Electric Motor: The history

Various scientists have been trying to create an economical and powerful engine since the first half of the 19th century. The basis was the discovery of M. Faraday, made in 1821. He discovered that a conductor placed in a magnetic field rotates.

In 1833, the inventor Thomas Davenport was able to design a DC motor, and later, in 1834, the scientist B.S. Jacobi came up with a prototype of the modern model of a rotating shaft motor.

A device more similar to modern units appeared in 1886, and the electric motor continues to improve to this day. Nowadays, there are many types of electric motors, but these discoveries were vital to the further development of motors.

Electric Motor Distribution Company

HVH Industrial Solutions is a distributor of electric motors (and not only) located in New Jersey, USA. Our company works with such popular motor manufacturers as WEG, Elektrim, Toshiba, MGM, Aurora Motors, etc.

Our company works closely with these famous brands and offers the best prices. You can check our catalog or send a quote.

You can find various types of electric motors on our website. You can check the Pump, Severe Duty, Brake, and General-purpose motors catalog. All motors are introduced with their main specifications, so you can find the right one you need.

You can also search for motors by their standards.

NEMA and IEC standards for motors

Like many other industrial products, electric motors also have standards. North American motor standards(compiled and published by NEMA) are consensus standards and are generally accepted within the United States, Canada, Mexico, and other countries using 60 Hz power.

However, motor specifiers must be familiar with standards such as IEC for companies exporting machinery and equipment outside of the US and Canada.

IEC standards are adopted by the convention and have the force of law in the European Community.IEC standards are also adopted by consensus (not legally binding) in regions outside the EEC where 50 Hz power is used. This includes sections of Eastern Europe, Africa, and portions of Asia.

IEC motor standards differ in many ways from North American standards. This includes:

- IEC standards use the SI system of units.

- IEC standards cover both 50 and 60-Hz motors.

- Standard IEC motors have speed and torque characteristics similar but not identical to NEMA Design A and B motors; there are no IEC equivalents for motor designs C and D.

- Standard IEC motors often have higher locked rotor currents than the equivalent North American B designs but are similar to A designs.

- IEC standards define nine types of duty cycles. The IEC definition for continuous duty (type Si) is similar to North American motors.

- Shaft extension, C-face, and D-flange dimensions for IEC motors differ from North American motors.

- IEC frame designations are from 56 to 355L. The numbers indicate the approximate distance from the floor to the centerline of the shaft in millimeters.

- EU countries have developed stringent EN 50 014 and EN 50 018 standards for explosion-proof motors and motors for other hazardous areas. A motor that has been tested, listed, or found to comply with North American hazardous area standards should not be assumed to comply with IEC standards or vice versa.

Interesting facts about electric motors: Industrial and General purpose motors

Now let's talk about electric motor facts. As we already mentioned, there are two main types of motors: AC and DC motors. Here are ten facts:

- Have you ever heard of a single molecular electric motor? Please don't get upset; it's a fact. It is the smallest electric motor globally, made from a single butyl methyl sulfide molecule.

- The first industrial electric motor was developed in 1834 by the Russian scientist Boris Semyonovich Jacobi(also known as Moritz Hermann). Jacob managed to increase the power of the electric motor to 550 watts.

- The first electric motor on a ship was used on September 13, 1838.

- A simple DC motor consists of six main parts: an armature(rotor), brushes, an axle, a commutator, a field magnet, and a DC power supply of some sort.

- Almost all toys that make any movement have motors.

- The British scientist Michael Faraday first demonstrated the principle of converting electrical energy into mechanical energy in 1821. So he is officially considered the inventor of the electric motor.

- The "Faraday Motor" is often demonstrated in school physics classes, with one difference, brine is used instead of toxic mercury.

- One of the most influential electric motors is the 36.5 megawatt (49,000 horsepower) HTS engine developed by Northrop Grumman Corporation.

- Nikola Tesla is considered the inventor of the three-phase generator.

- The market for electric motors is enormous. Electric motor sales worldwide in 2020 were about $142.7 billion.