Please Note: Photo may not represent actual item, please refer to title and product specifications for all details.

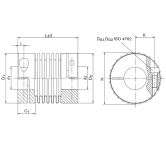

DKN-4 Miniature metal bellows coupling with clamping hubs

DKN-4 Miniature metal bellows coupling with clamping hubs is perfectly qualified for backlash-free connections in confined spaces. It is mounted on driver and driven components by means of clamping hubs. High-quality build and material guarantee for maximum durability. Backlash-free Metal bellows coupling are used in the sector of mechanical engineering, where a torque or a rotary motion has to be transmitted from shaft to shaft in highest accuracy of angle.

MPN: DKN-4

Specifications

| total length | 1.102 |

| min. bore diameter | 0.118 |

| max. bore diameter | 0.315 |

| outer diameter hub | 0.63 |

| clearance diameter | 0.709 |

| transmissible torque at given ta | 0.4 |

| max. rotation speed | 15000 |

| max. permissible axial misalignment | 0.016 |

| max. permissible angular misalignment | 2 |

| max. permissible radial misalignment | 0.008 |

| tightened torque of clamping screw dg1 | 0.2 |

Related Items

DKN-9 Miniature metal bellows coupling with clamping hubs

DKN-9 Miniature metal bellows coupling with clamping hubs

DKN-9 Miniature metal bellows coupling with clamping hubs is perfectly qualified for backlash-free connections in confined spaces. It is mounted on driver and driven components by means of clamping hu...Read more

DKN-9 Miniature metal bellows coupling with clamping hubs

DKN-9 Miniature metal bellows coupling with clamping hubs

DKN-9 Miniature metal bellows coupling with clamping hubs is perfectly qualified for backlash-free connections in confined spaces. It is mounted on driver and driven components by means of clamping hu...Read more

DKN-9 Miniature metal bellows coupling with clamping hubs

DKN-9 Miniature metal bellows coupling with clamping hubs

DKN-9 Miniature metal bellows coupling with clamping hubs is perfectly qualified for backlash-free connections in confined spaces. It is mounted on driver and driven components by means of clamping hu...Read more

DKN-15 Miniature metal bellows coupling with clamping hubs

DKN-15 Miniature metal bellows coupling with clamping hubs

DKN-15 Miniature metal bellows coupling with clamping hubs is perfectly qualified for backlash-free connections in confined spaces. It is mounted on driver and driven components by means of clamping h...Read more

DKN-15 Miniature metal bellows coupling with clamping hubs

DKN-15 Miniature metal bellows coupling with clamping hubs

DKN-15 Miniature metal bellows coupling with clamping hubs is perfectly qualified for backlash-free connections in confined spaces. It is mounted on driver and driven components by means of clamping h...Read more

Featured Items

MXN00630 WorkStar® 630 Technician's Rechargeable Headlamp

MXN00630 WorkStar® 630 Technician's Rechargeable Headlamp

The WorkStar® 630 Technician's Rechargeable Headlamp is a professional headlamp that produces 700/400/150 lumens, runs for 2/4/8 hours.

In stock

Simatool - BP 61 Bearing Puller Kit by Simatec

Simatool - BP 61 Bearing Puller Kit by Simatec

BP 61 bearing puller set is designed for easy and quick dismounting of deep groove ball bearings with interference fit on both rings. This ideal tool assortment is suitable for bearing sizes from 1...Read more

Simatool - TP 150 Twin Puller Kit

Simatool - TP 150 Twin Puller Kit

The simatool Twin Puller TP 150 can be used to professionally remove deep groove ball bearings and radial shaft seals, regardless of the installation position. 3 dismounting functions in 1 case: to...Read more

Simatherm - Induction Heater IH 025 Volcano

Simatherm - Induction Heater IH 025 Volcano

The simatherm IH 025 VOLCANO is a portable induction heater for heating small ferritic workpieces. It marks the start of a new era in the field of portable induction heaters. You can use it to heat...Read more

In stock