Electromagnetic Brakes

The main principle of electromagnetic brakes is using electromagnetism to accomplish frictionless braking. A magnetic flux passes in a perpendicular direction to the rotating wheel. A rapid current flowing in a direction opposite to the wheel's rotation creates an opposing force to the wheel rotation, which reduces and slows down the speed. Electromagnetic brakes are also called electro-mechanical brakes or EM brakes.

In the early twentieth century, electromagnetic brakes were used to ensure the safety and efficiency of trains and tram tracks. Nowadays, electromagnetic brakes are used in robotics, power tools, engineering, transport, aircraft, copy machines, conveyor drives, packaging, printing, food processing, and factory automation.

HVH Industrial works with manufacturers' specialized engineering teams to meet our customers' requirements and highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Electromagnetic Brakes

Manufacturers

When it comes to stopping or slowing down a moving object, brakes are an essential component of any mechanical system. In recent years, electromagnetic brakes have gained popularity as efficient and reliable braking solutions in various industries. In this article, we will delve into the basics of electromagnetic brakes, how they work, their types, and their advantages.

The basic principle of a brake system is to convert the kinetic energy of a moving object into heat energy through friction. In traditional braking systems, mechanical or hydraulic brakes are used, but electromagnetic brakes offer several advantages over these systems, such as improved response time, reduced maintenance, and higher accuracy.

What are Electromagnetic Brakes?

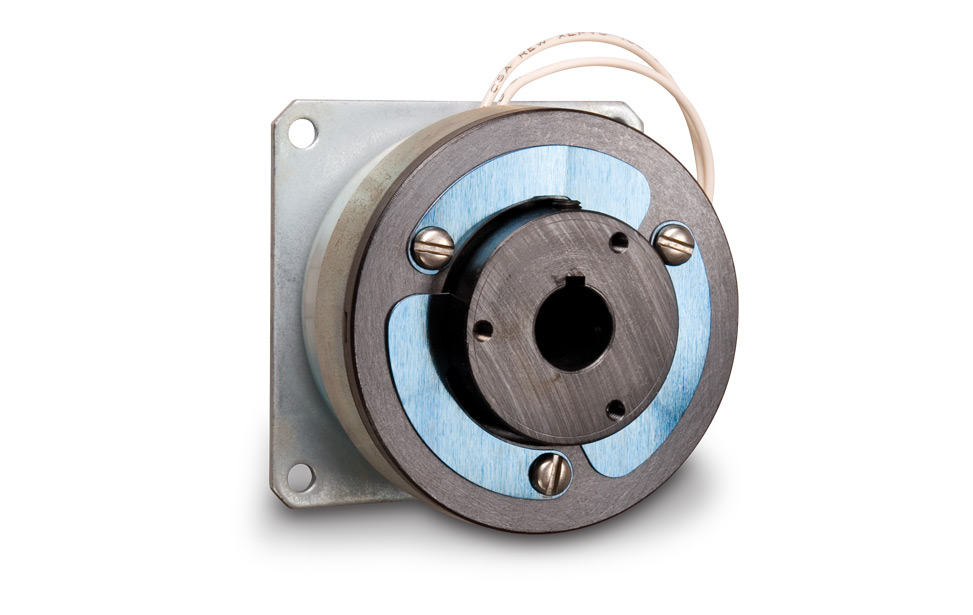

An electromagnetic brake is a type of brake that uses the principles of electromagnetism to stop or slow down a moving object. It comprises two main components: an electromagnet and a stationary armature. When the electromagnet is energized, it creates a magnetic field that attracts the armature and generates friction between the moving parts, thus slowing down or stopping the object.

Working Principle of Electromagnetic Brakes

The fundamental principle behind electromagnetic brakes is the conversion of electrical energy into mechanical energy through the use of magnetic fields. When current flows through a coil, a magnetic field is created, and the resulting magnetic force attracts or repels an object depending on its polarity. In the case of electromagnetic brakes, a rotating object (such as a wheel) is brought to a stop by using the magnetic force generated by an electromagnetic coil.

To apply the brake, the current is passed through the coil, creating a magnetic field. The brake's rotor is attracted to the stator's stationary magnetic field, causing it to stop rotating. When the current is removed, the rotor is released, and the object resumes rotation.

Types of Electromagnetic Brakes

There are several types of electromagnetic brakes available in the market, and some of the commonly used ones include:

Power Off Brakes

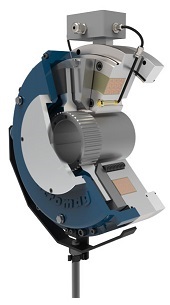

Power-off brakes are also known as fail-safe brakes. They are used in applications where it is critical to stop the equipment in case of a power failure. These brakes are designed to hold the equipment in a stopped position when there is no power supply. They work by using a spring to push the rotor away from the stator when the power is off. The spring force is stronger than the magnetic force, which ensures that the rotor stays in the released position when the power is off.

Power-off brakes are commonly used in applications such as elevators, cranes, hoists, and other machinery that require a fail-safe mechanism. They are reliable, efficient, and easy to maintain.

Spring Applied Brakes

Spring-applied brakes are also known as normally closed brakes. They are used in applications where it is necessary to hold the equipment in a stopped position when the power is on. These brakes work by applying a spring force that pushes the rotor toward the stator when the power is off. The spring force is weaker than the magnetic force, which allows the rotor to move freely when the power is on.

Spring-applied brakes are commonly used in applications such as printing presses, conveyor systems, and other machinery that require precise positioning. They are reliable, efficient, and easy to operate.

Electric Jaw Brakes

Electric jaw brakes are also known as toothed brakes. They are used in applications where it is necessary to transmit torque in both directions. These brakes work by using a series of teeth that engage with the rotor when the power is on. The teeth create a frictional force that can be used to slow down or stop the equipment. When the power is off, the teeth disengage and the rotor is released.

Electric jaw brakes are commonly used in applications such as machine tools, printing presses, and other machinery that require a high level of precision. They are reliable, efficient, and easy to maintain.

Hysteresis brakes

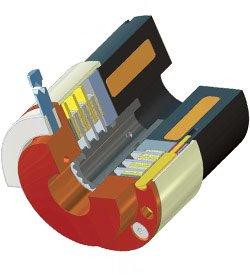

Hysteresis brakes are unique in that they do not have any physical contact between the rotor and the stator. Hysteresis brakes are electromagnetic brakes that work on the principle of hysteresis. Hysteresis is the phenomenon where the magnetic field of a material lags behind the applied magnetic field. Hysteresis brakes use this principle to generate torque and slow down or stop the machinery.

Hysteresis brakes consist of two parts, a stationary part, and a rotating part. The stationary part contains the electromagnet, while the rotating part consists of a magnetic rotor. When a voltage is applied to the electromagnet, it generates a magnetic field that induces eddy currents in the rotor. The eddy currents produce a magnetic field that lags behind the magnetic field of the electromagnet, generating torque that slows down or stops the rotor. They are commonly used in applications where precise torque control is required, such as medical equipment and laboratory instruments.

Advantages of Electromagnetic Brakes

High Torque Capacity: Electromagnetic brakes can handle high torque capacities, making them suitable for heavy machinery applications.

Quick Response Time: Electromagnetic brakes have a quick response time, which is crucial in applications that require fast braking.

High Accuracy: Electromagnetic brakes can provide high accuracy in stopping or holding a moving object, making them suitable for precision applications.

Safety: Electromagnetic brakes are a safe option because they do not rely on hydraulic or pneumatic systems, which can leak or fail.

Factors to Consider when Choosing Electromagnetic Brakes

Application: The type of application will determine the size and torque capacity required for the electromagnetic brake.

Power Supply: The power supply required for the electromagnetic brake must be considered to ensure it can handle the required voltage and current.

Environment: The environment in which the electromagnetic brake will be used must be considered, as factors such as temperature, humidity, and dust can affect the performance of the brake.

Mounting and Space Requirements: The mounting and space requirements of the electromagnetic brake must be considered to ensure it can be properly installed and does not interfere with other machinery components.

In conclusion, electromagnetic brakes are an essential part of modern machinery and equipment. They are used in various applications where stopping or holding the movement of mechanical equipment is required. Electromagnetic brakes work by converting electrical energy into mechanical energy and vice versa. They are reliable, efficient, and easy to operate.