Difference Between Synchronous and Asynchronous Motors

Electric motors are the workhorse of the transmission industry, and that's a fact. It converts the energy received from electricity into rotational motion for use in homes, industries, and just about anywhere. There are two main classes of electric motors: those that run on alternating current, called AC, and those that run on direct current, or DC. AC motors can be divided into two main categories: Synchronous and Asynchronous motors.

Synchronous Motors

Synchronous motors run at a constant speed regardless of the load acting on them. They are highly efficient motors that are best suited to high-precision applications.

The interaction between a rotating and a constant magnetic field leads the motor to run at a constant speed. The rotating magnetic field is produced by the stator of the synchronous motor, while the rotor creates a constant magnetic field. The field coil stator is excited by a three-phase AC supply and produces a rotating magnetic field with a synchronous speed. At the same time, the rotor is excited by a DC power supply and acts as a permanent magnet. Also, the rotor can be made of permanent magnets.

The synchronous motor is not self-starting, as the rotor needs an initial rotation. A squirrel cage arrangement is fitted through the pole tips to make the synchronous motor self-start. At the start, the rotor coils are not energized, but with the revolving magnetic field, electricity is induced in the squirrel cage bars, and the rotor starts rotating. The rotor's and rotating magnetic field's opposite poles attract each other and lock magnetically, which leads the rotor to rotate at the same speed as the rotating magnetic field.

A synchronous motor will go out of synchronism in case of a low voltage supply, low excitation voltage, and in case of motor overload.

Features & Benefits

-

Low inrush currents

-

Improved system power factor

-

High-efficiency ratings

-

Electromagnetic power varies linearly with power

-

Ease of alignment, more significant air gap

-

Constant speed with varying load

Asynchronous Motors

With the invention of the induction motor more than a hundred years ago, Nikola Tesla changed the course of human civilization. The induction motor is still the most common type used today, as more than 45% of the global electric power consumption is due to induction motors. Also, around 90% of motors used in industrial applications are induction motors.

An asynchronous motor is also known as an induction motor. Asynchronous means that the motor operates at less than its synchronous speed. The synchronous speed is the speed of rotation of the magnetic field in the rotor. Synchronous speed is dependent on the frequency and number of poles.

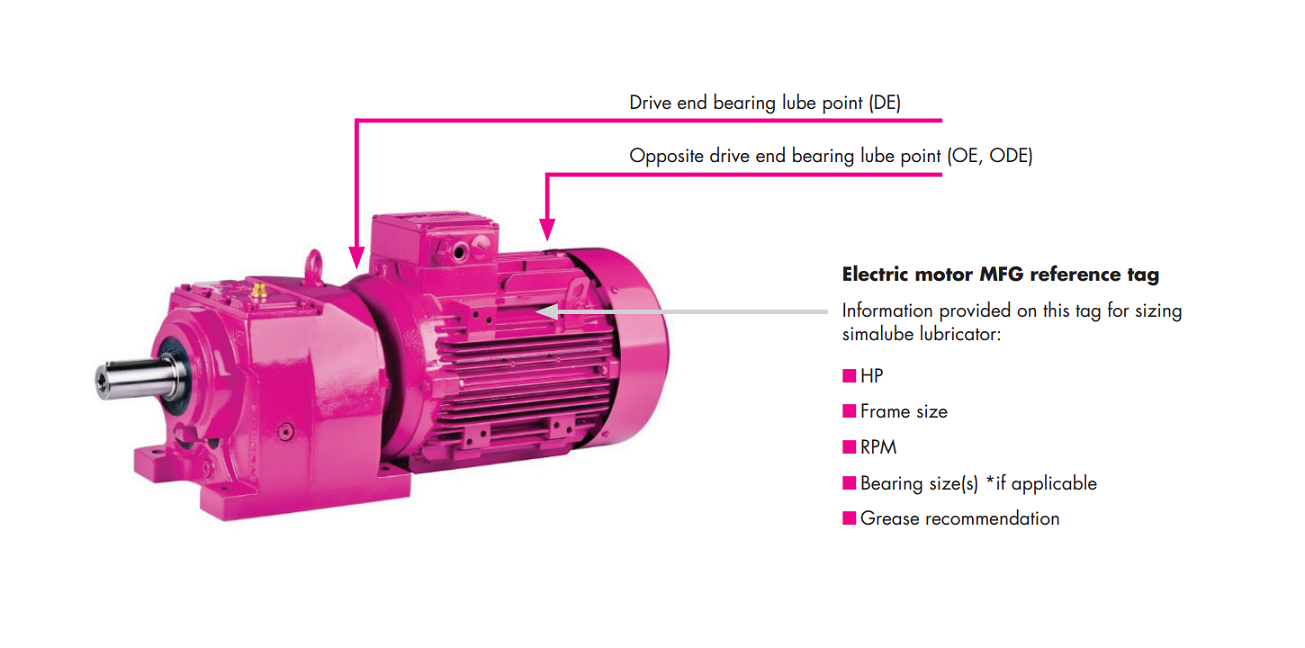

The two main parts of an induction motor are the stator and the rotor. Brass coils are placed in the stator and are separated from each other by ducts of ferromagnetic material. Plastic elements electrically isolate the wires to avoid short circuits. Inside the rotor, horizontal lines are visible, created by the squirrel cage, and foil layers make vertical lines. The bearings hold the crankshaft and the end shields, allowing the rotor to stay at the center stator winding and rotate with minimal friction.

A rotating magnetic field is created around the stator by an AC supply. The relative speed between the stator's magnetic field and the rotor's conductors causes an induced electromagnetic field in the rotor conductors. Electricity is induced on the rotor because of electromagnetic induction, not electrical wiring connections.

The induced current in the rotor creates an alternating flux around it. The rotor's flux lags behind the stator's flux, rotating in the same direction, trying to catch up with the synchronous speed and never reaching it.

Induction motors are widely used in residential, commercial, and industrial applications because of their simple design, affordable price, low maintenance cost, and high reliability.

Features & Benefits

-

Simple and rugged design

-

Minimum maintenance

-

Higher starting torque capability

-

Low cost

-

Efficient in partial-load operations

Synchronous Vs. Asynchronous Motors

-

Synchronous motor runs at a fixed speed at a given frequency irrespective of the load. However, the rate of an asynchronous motor reduces with the increase in the load.

-

Synchronous motors can be run at ultra-low speeds(below 300 rpm) by utilizing high-power electronic converters that generate low frequencies. Asynchronous motors are excellent for speeds above 600 rpm.

-

A synchronous motor is not self-starting, whereas an asynchronous motor can be self-started. An additional winding called damper winding provides the starting torque.

-

An external DC excitation is required for the synchronous motor to start; however, an asynchronous motor does not require any external excitation to run.

Feel free to Contact Us if you have any questions, need more information, or are interested in purchasing a synchronous or asynchronous electric motor.

HVH Industrial Solutions is an authorized distributor of WEG, LEESON Motors, Marathon Motors, Aurora Motors, Elektrim Motors, WorldWide Electric, Toshiba, Brook Crompton, MGM Electric Motors, Lafert and many others. We work closely with their engineering team to provide superior customer service and engineering support.