Ball Splines

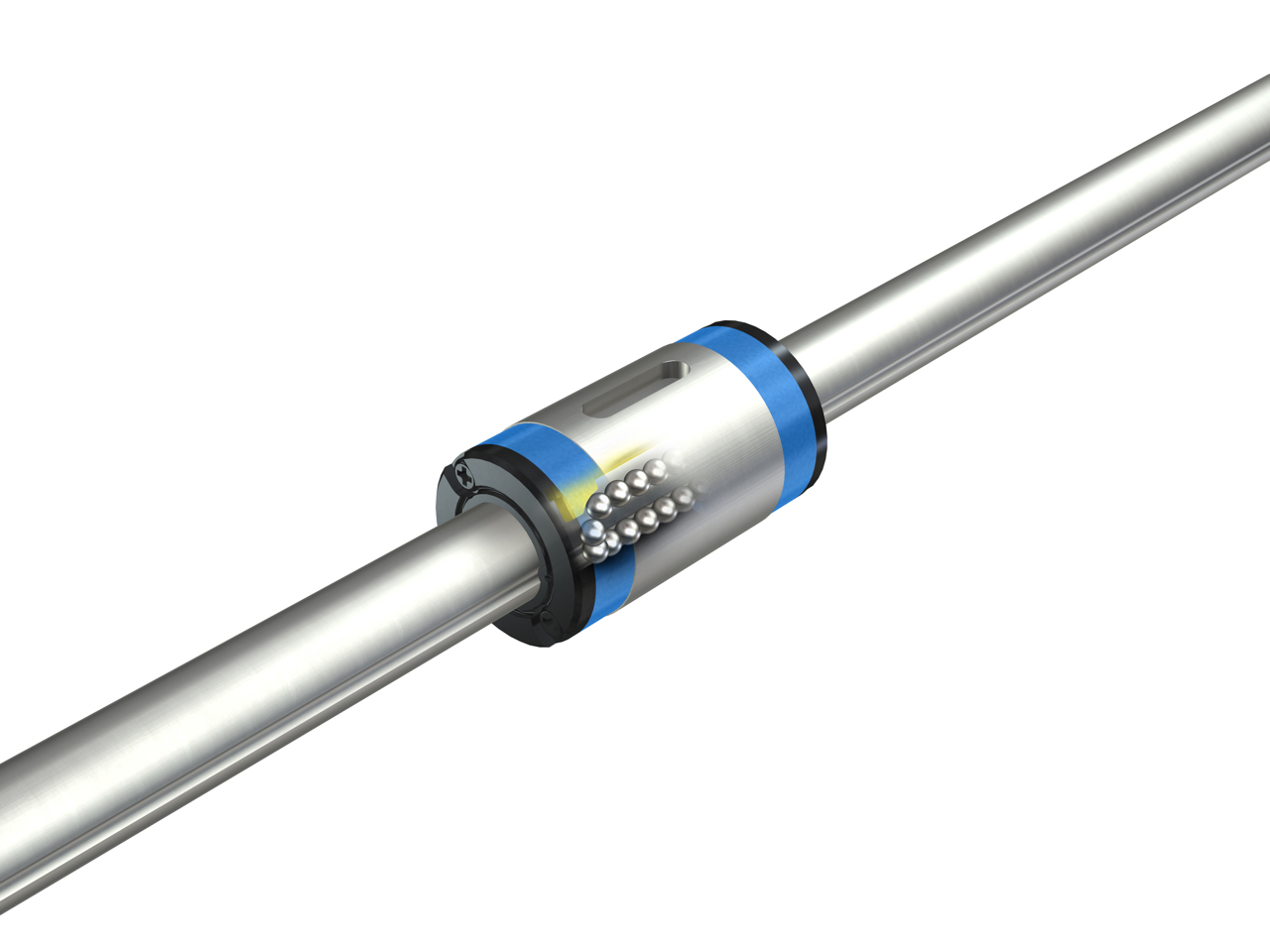

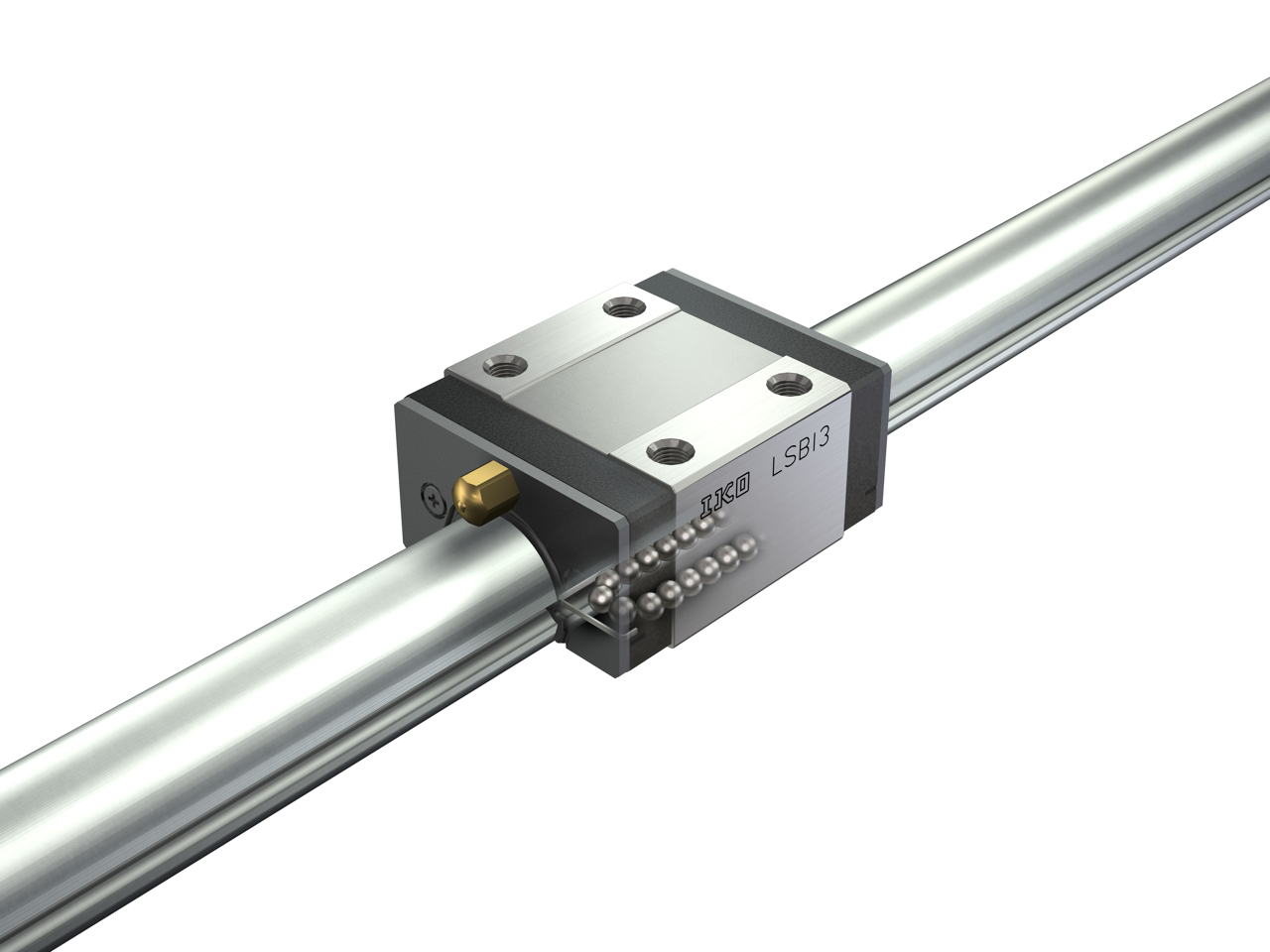

A ball spline is a type of rolling bearing linear guide, but with different operating functions. A ball spline consists of a linear bushing and shaft system, with axial grooves along the shaft and the inner diameter of the nut. Load-carrying balls recirculate within the nut, and the grooves in the shaft prevent rotation and facilitate the transmission of torque. The resulting contact allows for high load capability than linear bushings with the advantage of torque transmission while undertaking the linear movements.

Standard ball splines provide both linear motion and torque transmission, while rotary ball splines consist of a rotating element (angular contact ball bearings, crossed rollers, or gears) on the outer diameter of the nut, which provides rotary motion in addition to the linear motion of the ball spline itself.

HVH Industrial works with the specialized engineering teams of manufacturers to meet our customer's requirements and the highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Ball Splines

Manufacturers

What is a Ball Spline

A ball spline is a specialized type of linear guide that offers both linear motion and torque transmission. Unlike conventional linear bushings, which primarily facilitate linear movement, ball splines provide the additional benefit of transmitting torque while undergoing linear movements. This feature makes them ideal for applications that require both rotational and linear motion.

Structure of a Ball Spline

A ball spline comprises two primary components: a linear bushing and a shaft system. The linear bushing, also known as the nut, houses the load-carrying balls and facilitates their recirculation. The shaft features axial grooves that match the internal grooves of the nut, preventing rotation while allowing linear movement. The number and arrangement of grooves may vary based on the specific design and manufacturer.

How Ball Splines Work

When an external force is applied to a ball spline, the load-carrying balls transmit the load from the nut to the shaft, enabling linear motion. The grooves on the shaft act as channels for the balls to circulate, ensuring smooth movement. Simultaneously, the grooves prevent the rotation of the nut, maintaining the desired orientation of the linear motion. This design allows the ball spline to carry significant loads while facilitating torque transmission.

Advantages of Ball Splines

Ball splines offer several advantages over other linear motion systems:

High Load Capability: Ball splines can handle substantial loads due to the recirculating ball mechanism and the efficient load distribution across multiple balls.

Torque Transmission: In addition to linear motion, ball splines can transmit torque, making them suitable for applications that require both linear and rotational movement.

Compact Design: Ball splines are relatively compact, allowing for efficient use of space in mechanical systems.

Smooth and Precise Motion: The ball recirculation system ensures smooth and precise linear motion, contributing to accurate positioning and smooth operation.

Long Service Life: Properly maintained ball splines can provide a long service life, reducing maintenance and replacement costs.

Applications of Ball Splines

Ball splines find application in a wide range of industries and fields. Some common areas where they are utilized include:

- Industrial automation and robotics

- Machine tools and CNC equipment

- Packaging and material handling systems

- Semiconductor manufacturing equipment

- Printing and paper processing machinery

- Medical and Scientific Instruments

Conclusion

Ball splines provide a versatile solution for applications that require both linear motion and torque transmission. With their unique design and recirculating ball mechanism, ball splines offer high load capability, smooth motion, and precise positioning. By understanding their structure, working principles, and applications, you can make informed decisions when selecting and utilizing ball splines in your mechanical systems.