Flexible Couplings

Flexible Couplings are designed to transmit power from one shaft to another, providing protective functions such as vibration dampening, high torque capacity, and compensation of minor misalignments. They can be used in various applications, including printing machines, machine tools, compressors, welders, blowers, etc.

We offer various flexible couplings, such as Superflex Super-Elastic Couplings, couplings with hubs with keyway connections, hubs with backlash-free clamping connections, hubs with mounting flange connections, and hub combinations.

HVH Industrial works with manufacturers' specialized engineering teams to meet our customers' requirements and highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Flexible Couplings

Manufacturers

What are Flexible Couplings?

Flexible couplings are mechanical devices designed to connect two shafts while transmitting power from one to the other. Unlike rigid couplings, flexible couplings allow for slight misalignments between shafts, compensating for axial, radial, and angular deviations. These deviations often arise due to inherent imperfections in manufacturing or environmental factors.

Functions of Flexible Couplings

Vibration Dampening

One of the critical functions of flexible couplings is vibration dampening. Mechanical systems often generate vibrations during operation, which can lead to premature wear and reduced efficiency. Flexible couplings absorb and dissipate these vibrations, protecting sensitive components and extending the service life of the machinery.

High Torque Capacity

Flexible couplings are capable of transmitting high levels of torque between shafts without introducing excessive stress. This ability makes them ideal for applications involving heavy machinery or systems requiring substantial power transfer.

Compensation for Minor Misalignments

Shaft misalignments are inevitable in most mechanical systems, especially when multiple components are interconnected. Flexible couplings excel at accommodating these minor misalignments, ensuring smooth and reliable power transmission.

Types of Flexible Couplings

Superflex Super-Elastic Couplings

Superflex Super-Elastic Couplings are innovative and highly flexible couplings that offer superior torsional elasticity. They can compensate for significant shaft misalignments, providing enhanced protection to machinery and reducing the risk of mechanical failures.

Couplings with Hubs with Keyway Connections

Hubs with keyway connections offer a secure and precise method of connecting shafts. The keyway ensures proper alignment, preventing slippage and optimizing power transmission efficiency.

Hubs with Backlash-Free Clamping Connections

Backlash-free clamping connections provide a robust and backlash-free connection between the coupling and the shaft. This design is particularly suitable for applications requiring high precision and responsiveness.

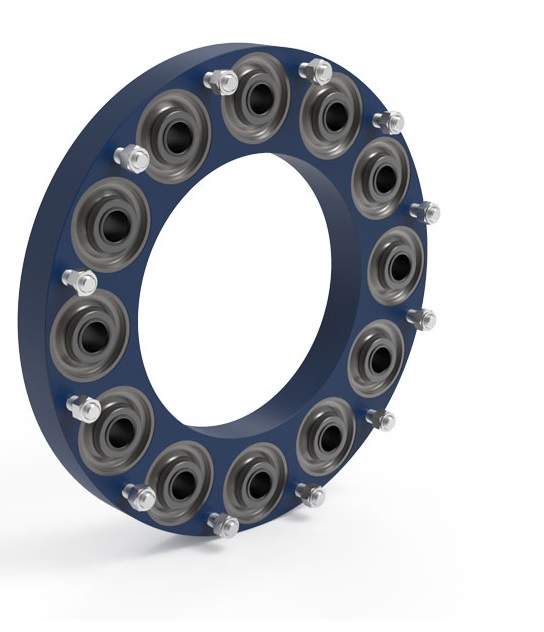

Hubs with Mounting Flange Connections

Hubs with mounting flange connections offer a convenient means of installation. They are widely used in various mechanical systems due to their ease of assembly and disassembly.

Hub Combinations

Hub combinations allow users to customize the coupling according to their specific requirements. By choosing different hubs, engineers can achieve optimal performance and adaptability in diverse applications.

Applications of Flexible Couplings

Printing Machines

In the printing industry, precise and smooth power transmission is crucial for achieving high-quality print results. Flexible couplings are employed in printing machines to reduce vibrations and ensure consistent and accurate printing.

Machine Tools

Machine tools require reliable power transmission to deliver precise cutting, shaping, and machining operations. Flexible couplings enable seamless power transfer, contributing to the accuracy and efficiency of machine tools.

Compressors

Compressors play a vital role in various industries, from refrigeration to manufacturing. Flexible couplings protect compressor components from excessive stress and vibrations, enhancing their operational life.

Welders

Welding machines need consistent power transmission for stable and uniform welding processes. Flexible couplings aid in damping vibrations, resulting in better weld quality and reduced defects.

Blowers

Blowers are used to circulate air or gas in numerous applications, including ventilation and aeration. Flexible couplings contribute to the smooth operation of blowers, minimizing noise and ensuring reliable performance.

Advantages of Using Flexible Couplings

Increased Service Life of Machinery

By reducing the impact of vibrations and accommodating misalignments, flexible couplings extend the service life of machinery and equipment, reducing downtime and maintenance costs.

Reduced Maintenance Costs

The ability of flexible couplings to dampen vibrations and compensate for misalignments translates into lower maintenance requirements, saving both time and money.

Enhanced Power Efficiency

Flexible couplings optimize power transmission, ensuring minimal energy losses during operation. This leads to enhanced power efficiency and reduced energy consumption.

Factors to Consider When Selecting Flexible Couplings

Operating Conditions

The operating environment, including temperature, humidity, and potential exposure to chemicals or abrasive materials, must be considered when selecting a flexible coupling. Ensuring that the chosen coupling can withstand these conditions will guarantee its longevity and performance.

Torque Requirements

Different applications demand varying levels of torque transmission. Understanding the specific torque requirements of the machinery or equipment is crucial in choosing the appropriate flexible coupling to handle the intended load.

Shaft Misalignments

Analyzing the potential misalignments between shafts is essential in determining the type of flexible coupling needed. Identifying the degree of misalignment will help in selecting a coupling that can adequately compensate for these deviations.

Installation Space Constraints

The available space for coupling installation can be limited in certain applications. It's vital to choose a flexible coupling that fits within the designated space without hindering the overall efficiency of the mechanical system.

Conclusion

Flexible couplings play a vital role in modern mechanical systems, providing the means to transmit power efficiently and reliably while compensating for misalignments and vibrations. Understanding the different types of couplings available and their applications can help engineers and manufacturers make informed decisions for their specific needs.

Here at HVH, we offer a wide range of flexible couplings, including the advanced Superflex Super-Elastic Couplings and various hub connections. Our products are engineered with precision and quality, ensuring optimal performance and durability in diverse industrial applications.