High-Precision Positioning Tables

HVH offers a wide range of High-Precision Positioning Tables driven by ball screws that act as reliable positioning mechanisms in a variety of applications as a positioning mechanism for the state-of-the-art LCD and semiconductor manufacturing facilities such as measuring equipment, processing machines, and assemblers.

HVH Industrial works with the specialized engineering teams of manufacturers to meet the requirements and highest quality standards of our customers.

If you have any questions, write us via live chat, (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

High Precision Positioning Tables

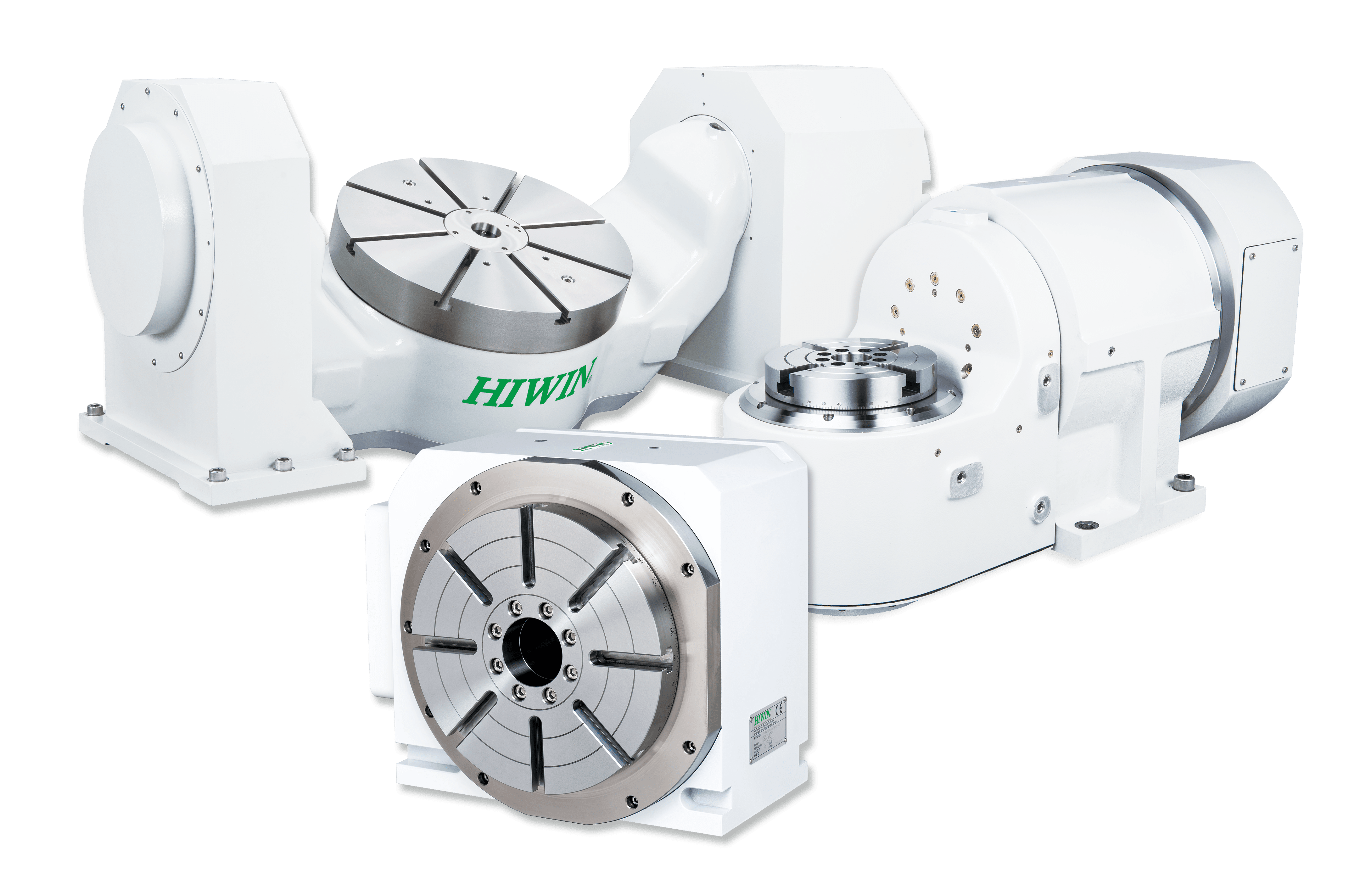

Manufacturers

In the world of advanced manufacturing, precision and accuracy are paramount. The need for high-precision positioning mechanisms is essential in various applications, ranging from state-of-the-art LCD and semiconductor manufacturing facilities to measuring equipment, processing machines, and assemblers. One such reliable positioning mechanism is the high-precision positioning table driven by ball screws.

What are High-Precision Positioning Tables

High-precision positioning tables are advanced mechanical devices designed to provide precise and accurate motion control. These tables, commonly found in manufacturing environments, play a crucial role in ensuring the precise positioning of components, tools, or workpieces. With their exceptional accuracy, reliability, and repeatability, high-precision positioning tables are indispensable in industries where even the slightest error can have significant consequences.

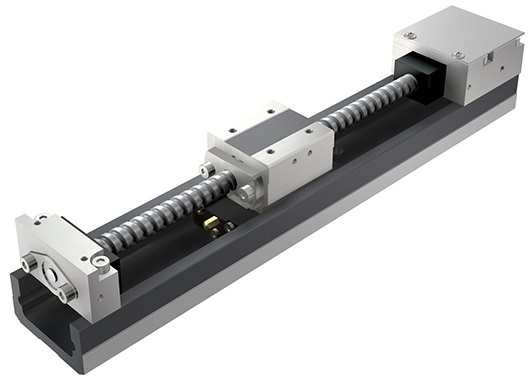

The Role of Ball Screws in Positioning Mechanisms

Ball screws serve as the driving force behind high-precision positioning tables. They are a type of mechanical linear actuator that converts rotational motion into linear motion. A ball screw consists of a threaded shaft (screw) and a ball nut with recirculating ball bearings. As the screw rotates, the ball bearings move between the screw and the nut, translating the rotational motion into linear movement.

The use of ball screws in positioning mechanisms offers several advantages. Firstly, ball screws provide high efficiency, converting a large portion of the input torque into linear motion. This efficiency ensures minimal energy loss, making them ideal for applications where energy consumption is a concern. Additionally, ball screws exhibit low friction, resulting in smooth and precise movement.

Benefits of High-Precision Positioning Tables

Exceptional Precision: High-precision positioning tables offer unparalleled accuracy, allowing for precise positioning down to micrometer-level measurements. This precision is crucial in industries such as semiconductor manufacturing, where even the tiniest deviations can lead to faulty products.

Repeatable Performance: These positioning tables provide excellent repeatability, ensuring consistent and reliable positioning throughout multiple operations. This feature is vital in applications that require repeated and accurate positioning, minimizing the risk of errors or defects.

Stability and Rigidity: High-precision positioning tables are designed to be highly stable and rigid, minimizing vibration and deflection during operation. This stability is critical for maintaining positional accuracy, especially in high-speed or high-load scenarios.

Flexibility and Customizability: Manufacturers offer a wide range of high-precision positioning tables with varying sizes, load capacities, and travel distances, allowing for customization based on specific application requirements. This flexibility ensures that the positioning table can be tailored to meet the unique needs of different industries.

Applications of High-Precision Positioning Tables

High-precision positioning tables find applications across various industries, playing a vital role in ensuring precise and reliable motion control. Some of the key applications include:

Semiconductor Manufacturing: High-precision positioning tables are extensively used in the production of semiconductor devices, where precise positioning is critical for processes like lithography, wafer inspection, and assembly.

LCD Manufacturing: The production of LCD panels demands accurate positioning during each stage, from glass cutting and edge polishing to layer deposition and alignment. High-precision positioning tables enable the precise control required for these processes.

Metrology and Measurement Equipment: Precision measurement equipment, such as coordinate measuring machines (CMMs) and optical comparators, rely on high-precision positioning tables to ensure accurate measurements and inspections.

Medical Device Manufacturing: High-precision positioning tables play a crucial role in the production of medical devices, where precision and accuracy are vital. They enable precise alignment, assembly, and testing of intricate components.

Conclusion

High-precision positioning tables driven by ball screws are indispensable in advanced manufacturing facilities. Their exceptional precision, stability, and customizability make them the ideal choice for applications that demand accurate motion control. From semiconductor manufacturing to metrology and medical device production, these positioning tables play a vital role in ensuring precise and reliable operations.