Lean Servo Motors

Lean servo motors are a type of synchronous servo motor produced by the German manufacturer Stober. The lean servo motor is known for its small, light, and compact design. Also, lean servos are less expensive and more rugged than standard synchronous servo motors with lower energy requirements and longer service life.

By eliminating the encoder, the Lean motor uses a single off-the-shelf power cable with no additional shielded wires. These are two factors that make it up to 30% cheaper than a comparable synchronous servo motor. Since the encoder is left out, the STOBER Lean motor can withstand high oscillations and vibrations. And the reduced wiring also makes commissioning so much easier!

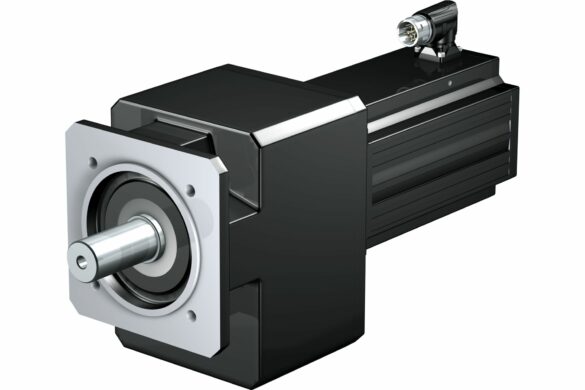

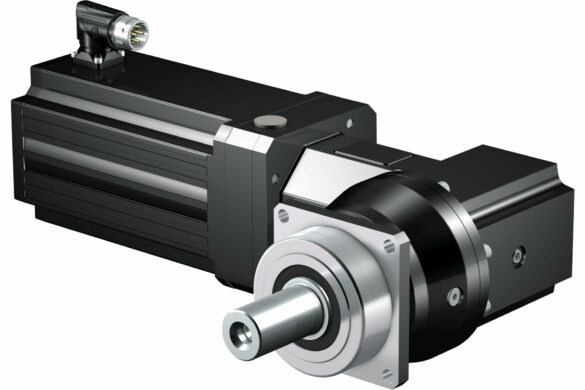

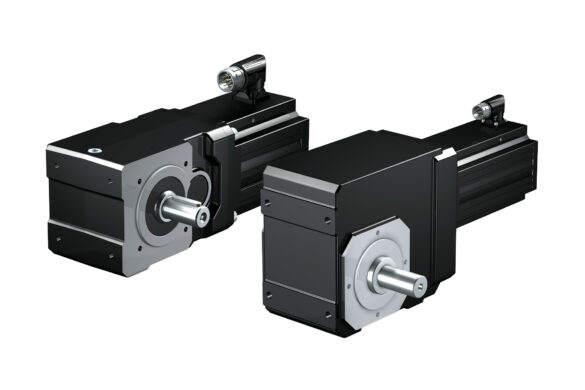

We offer a wide range of lean servo motors like Planetary Geared Lean Motors, Right-Angle Planetary Geared Lean Motors, Helical Bevel Geared Lean Motors, Helical Geared Lean Motors, and Offset Helical Geared Lean Motors.

Lean Servo Motor Features:

- Energy efficiency class: IE5 (highest class) in acc. with IEC/TS 60034-30-2

- Shaft: Solid shaft with feather key

- Brake: Optional robust spring-loaded holding brake on the motor’s B side

- Power interface:

- Rotating plug connectors with quick lock

- Encoderless motor, the position is determined via the power connection

- Correct position and speed determinations in combination with STOBER SC6 and SI6 drive controllers

- Speed deviation is less than 1%, positioning accuracy is ± 1°

- Cooling: Convection cooling

- Winding protection: PTC thermistors guarantee thermal winding protection

- Paint: RAL 9005 Jet black

- Marks and test symbols: CE and cURus

- Recommended drive controllers: STOBER drive controllers of the SC6 or SI6 series

Lean Motors (LM) Catalog Stober

HVH Industrial Solutions is an authorized distributor of Stober.

We work closely with the Stober engineering team to provide superior customer service and engineering support.

If you have any questions, write us via live chat (one of our team members will answer your questions), call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Lean Servo Motors

Manufacturers

In today's world, automation plays a significant role in various industries. It improves production efficiency, reduces labor costs, and increases product quality. One of the crucial components of automation is servo motors. These motors are widely used in industrial automation, robotics, CNC machines, and other applications where precise control is required. However, traditional servo motors have some limitations, such as high cost, large size, and high power consumption. To overcome these limitations, a new type of motor has emerged - Lean Servo Motor.

What are Lean Servo Motors?

Lean Servo Motors are a new type of motor that combines the advantages of both stepper and servo motors. They are designed to be smaller, more efficient, and more affordable than traditional servo motors. Unlike traditional servo motors, which use closed-loop control to achieve precise positioning, Lean Servo Motors use open-loop control, which simplifies the control system and reduces costs.

Stober lean motors work by utilizing permanent magnets that are mounted on the rotor. When an electric current is applied to the stator windings, a rotating magnetic field is created, which interacts with the magnets on the rotor, causing the motor to spin. The efficiency of the motor is optimized by reducing the rotor losses and minimizing the resistance in the motor windings.

Stober drive controllers are high-performance motor control units that are designed to work seamlessly with Stober lean motors. These controllers use advanced algorithms and control techniques to regulate the speed and torque of the motor, ensuring smooth and efficient operation. They come in a range of configurations to meet the diverse needs of industrial applications.

Features and Benefits of Lean Servo Motors

Compact Design

Lean Servo Motors have a compact design, making them easy to install and integrate into your automation system. Their small size also helps save space in your facility. Also, these motors are designed for easy maintenance, with a modular design that allows for quick and easy replacement of parts.

High Power Density

Lean servo motors have a high power density, which means they can provide high torque and speed in a compact size. This is especially useful in applications where space is limited, and high performance is required.

Accurate and Precise Motion Control

Lean servo motors provide accurate and precise motion control, which is essential in many industrial automation applications. The closed-loop control system ensures that the motor maintains a high level of accuracy and precision, which results in better product quality, reduced waste, and improved efficiency.

Energy Efficient

Lean servo motors are energy efficient, which means they consume less power than other types of motors. This results in lower energy costs, reduced carbon footprint, and improved sustainability.

Low Maintenance

Lean servo motors have a simple and robust design, which makes them easy to maintain. They require less maintenance than other types of motors, which results in lower maintenance costs and less downtime.

Applications of Lean Servo Motors

Robotics

Robotics is an industry where lean servo motors have proved to be highly effective. With the help of these motors, robots can be programmed to perform tasks with high accuracy and precision, which was not possible with traditional motors. These motors are also lightweight, which makes them perfect for use in small robots, which require precise movements.

CNC Machines

CNC machines are used in various industries for cutting, drilling, and shaping materials. The use of lean servo motors in these machines has made them more precise and efficient. These motors are capable of providing high torque at low speeds, which makes them perfect for use in CNC machines.

Medical Industry

The medical industry is another area where lean servo motors have proved to be highly beneficial. These motors are used in various medical devices, such as surgical robots, X-ray machines, and MRI machines. The high precision and accuracy of these motors make them perfect for use in these devices, where even a slight error can have serious consequences.

Printing Industry

The printing industry is another area where lean servo motors are being used to enhance efficiency and productivity. These motors are used in various printing machines, such as offset printing machines and digital printers. With the help of these motors, these machines can be programmed to produce high-quality prints with high precision and accuracy.

Packaging Industry

The packaging industry is another area where lean servo motors are being used extensively. These motors are used in various packaging machines, such as fillers, cappers, and labelers. With the help of these motors, these machines can be programmed to perform tasks with high precision and accuracy, which results in increased efficiency and productivity.

Why Choose Lean Motors?

If you are looking for a motor that is built to last and designed for maximum efficiency and reliability, then Lean Motors is the way to go. With their minimal waste design and high-performance capabilities, Lean Motors are an excellent choice for industrial and personal applications alike.

In addition to their performance capabilities, Lean Motors are also environmentally friendly, making them an excellent choice for those who are looking to reduce their carbon footprint.

At HVH Industrial Solutions, we are committed to providing our customers with the best quality motors on the market. We believe that Lean Motors are the ultimate choice for efficiency and reliability, and we are proud to offer them to our customers. Contact Us today to learn more about our selection of Lean Motors and how they can benefit you.