Profile Rail Bearings and Guides

Profile Rail Bearings and Guides are designed to utilize the motion of rolling elements. They feature low friction, no-slip, and smooth operation even under high load conditions. As these linear bearings provide high efficiency and high functionality for an extended period of time, they meet the needs of much industrial precision machinery.

HVH Industrial works with the specialized engineering teams of manufacturers to meet the requirements and highest quality standards of our customers.

If you have any questions, write us via live chat, (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Profile Rail Bearings and Guides

Manufacturers

Industrial precision machinery relies on the smooth and precise movement of components to ensure optimal performance. Profile Rail Bearings and Guides play a vital role in achieving this objective. By utilizing rolling elements, these bearings and guides enable smooth motion and enhance the overall efficiency of precision machinery. Let's explore their features, benefits, applications, and other essential aspects in detail.

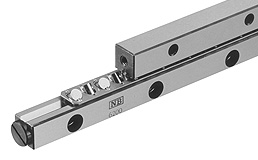

What are Profile Rail Bearings and Guides

Profile Rail Bearings and Guides are mechanical systems designed to facilitate linear motion. They consist of a rail and a carriage assembly. The rail serves as a track, while the carriage contains rolling elements, such as balls or rollers, which enable linear movement along the rail. This rolling motion reduces friction and allows for smooth and accurate linear movement. The design of the rail and carriage ensures stability and minimizes backlash, enhancing the overall performance of the system.

Features of Profile Rail Bearings and Guides

High Load Capacity: Profile Rail Bearings and Guides are engineered to withstand high loads, making them suitable for heavy-duty applications.

Low Friction: These bearings and guides offer low friction characteristics, reducing energy consumption and heat generation.

Precision and Accuracy: Profile Rail Bearings and Guides provide exceptional precision and accuracy, ensuring reliable and consistent motion control.

Rigidity: The design of these bearings and guides enhances rigidity, allowing for stable and controlled linear motion.

Long Service Life: With proper maintenance, Profile Rail Bearings and Guides can provide extended service life, reducing downtime and maintenance costs.

Applications of Profile Rail Bearings and Guides

Profile Rail Bearings and Guides find extensive use in numerous industries that rely on precision machinery. Some common applications include:

Machine Tools: Profile Rail Bearings and Guides are widely employed in machine tools, such as milling machines, lathes, and grinders, ensuring precise movement and positioning.

Robotics: These bearings and guides play a critical role in robotics, enabling smooth and accurate linear motion in robotic arms, gantries, and automation systems.

Material Handling Equipment: Profile Rail Bearings and Guides are used in conveyor systems, automated storage and retrieval systems (AS/RS), and other material handling equipment, ensuring reliable and efficient linear motion.

Medical Equipment: Precision is crucial in medical equipment, and Profile Rail Bearings and Guides provide the necessary motion control for devices like MRI machines, surgical robots, and laboratory automation systems.

Packaging and Printing Machinery: These bearings and guides facilitate precise movement in packaging and printing machinery, ensuring accurate positioning and high-quality output.

Factors to Consider when Selecting Profile Rail Bearings and Guides

When choosing Profile Rail Bearings and Guides for a specific application, several factors need to be taken into account, including:

Load Requirements: Assess the load capacity and load type to ensure the selected bearings and guides can withstand the intended application's demands.

Accuracy and Precision: Consider the required level of precision and accuracy for the application to ensure the bearings and guides meet the desired specifications.

Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and contamination levels, to choose bearings and guides that can withstand these conditions.

Installation and Maintenance: Consider the ease of installation and maintenance requirements to minimize downtime and associated costs.

Budget: Evaluate the cost-effectiveness of the bearings and guides while considering the overall requirements of the application.

Installation and Maintenance of Profile Rail Bearings and Guides

Proper installation and regular maintenance are essential for maximizing the performance and lifespan of Profile Rail Bearings and Guides. Here are some key steps to follow:

Installation: Follow the manufacturer's guidelines for proper installation, ensuring correct alignment and preload adjustment.

Lubrication: Apply the recommended lubricant to reduce friction and enhance the longevity of the bearings and guides.

Inspection: Regularly inspect the bearings and guides for signs of wear, damage, or contamination. Replace any components as necessary.

Cleaning: Keep the bearings and guides clean by removing dirt, debris, and contaminants that could impair their functionality.

Conclusion

Profile Rail Bearings and Guides are indispensable components in industrial precision machinery. Using rolling elements, these bearings and guides offer low friction, no-slip operation, and smooth motion even under high load conditions. Their high efficiency, functionality, and extended service life make them a preferred choice for various industries. Whether it's machine tools, robotics, material handling equipment, medical devices, or packaging machinery, Profile Rail Bearings and Guides play a crucial role in enhancing precision, accuracy, and overall performance.