Servo Couplings

Servo Couplings are the most demanding and are intended for industries requiring high precision positioning, high speed, and high reverse loading. The couplings feature zero backlash and low inertia and compensate for shaft misalignment in motion control applications. We offer various Servo Couplings, such as Bellows Couplings, Elastomer Couplings, Safety Couplings, and Distance Couplings.

HVH Industrial offers various servo couplings to meet our customers’ specific requirements.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Servo Couplings

Manufacturers

To achieve exceptional performance in motion control applications, industries rely on Servo Couplings. These couplings play a critical role in transmitting torque and compensating for shaft misalignment, ensuring seamless operation even under high reverse loading conditions. In this article, we will explore the significance of Servo Couplings and the various types available, including Bellows Couplings, Elastomer Couplings, Safety Couplings, and Distance Couplings.

What are Servo Couplings?

Servo Couplings are specialized mechanical devices used to connect two shafts and transmit torque while compensating for any misalignment between them. They are extensively utilized in motion control systems, where precision and efficiency are critical. Servo Couplings offer the advantage of zero backlash, ensuring no delay in torque transmission during direction changes.

Importance of Servo Couplings in Motion Control

In motion control applications, precision and accuracy are essential to ensure seamless operation. Servo Couplings play a vital role in maintaining precise positioning and alignment between connected shafts, minimizing vibrations and ensuring optimal performance.

How Servo Couplings Work

Torque Transmission and Zero Backlash

Servo Couplings facilitate the seamless transfer of torque from one shaft to another without any backlash. The absence of backlash ensures immediate responsiveness during changes in direction, crucial in motion control systems.

Compensation for Shaft Misalignment

Shaft misalignment can occur due to various factors, such as thermal expansion or manufacturing tolerances. Servo Couplings can compensate for both angular and parallel misalignment, maintaining the precision of motion.

Low Inertia and High-Speed Capability

The low inertia of Servo Couplings allows for rapid acceleration and deceleration, making them suitable for high-speed applications. The reduced mass in the coupling ensures quick response times, contributing to improved system performance.

Applications of Servo Couplings

Robotics and Automation

In the field of robotics and automation, precise motion control is critical for efficient and safe operations. Servo Couplings enable robotic arms and joints to move with accuracy and repeatability.

Machine Tools and CNC Machining

Machine tools, such as lathes and milling machines, heavily rely on Servo Couplings for their positioning and motion control requirements. CNC machining centers benefit from the high precision offered by these couplings.

Printing and Packaging Industry

The printing and packaging industry demands precise registration and consistent operation. Servo Couplings play a vital role in ensuring smooth performance in printing presses and packaging machines.

Types of Servo Couplings

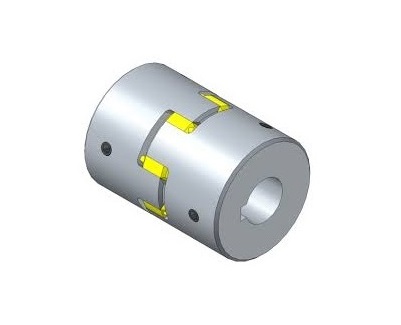

Bellows Couplings

Bellows Couplings are ideal for applications requiring high torsional stiffness and precise motion control. The accordion-like design of the bellows ensures flexibility while maintaining high torque transmission capabilities.

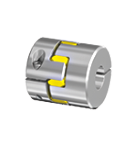

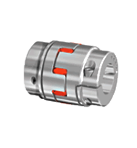

Elastomer Couplings

Elastomer Couplings excel in damping vibrations and shock absorption, reducing the impact of sudden changes in torque. They are commonly used in high-speed applications, where smooth and quiet operation is essential.

Safety Couplings

Safety Couplings are designed to protect machinery from sudden overloads and torque spikes. They act as a mechanical fuse, disconnecting the power transmission temporarily to prevent damage to expensive components.

Distance Couplings

Distance Couplings are used to bridge larger axial distances between shafts. They are particularly useful when dealing with applications where a certain level of misalignment is inevitable.

Comparing Servo Couplings with Other Coupling Types

Servo Couplings vs. Flexible Couplings

While both Servo Couplings and Flexible Couplings are used for misalignment compensation, the former offers superior precision and is better suited for high-performance applications.

Servo Couplings vs. Rigid Couplings

Rigid Couplings do not accommodate misalignment, making them less suitable for motion control applications where flexibility is necessary. Servo Couplings, with their ability to compensate for misalignment, provide a better solution.

Conclusion

Servo Couplings are indispensable components in motion control applications, serving industries that demand high precision positioning, speed, and reverse loading capabilities. With their zero backlash, low inertia, and misalignment compensation features, Servo Couplings play a crucial role in achieving seamless and efficient operation.