HVH Industrial Solutions is a leading supplier of indexable tools and inserts

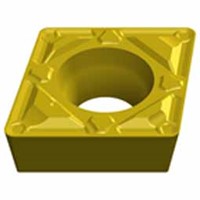

Indexable tools and inserts are carbide-cutting products for general-purpose machining and several special applications, such as grades, coatings, chip breakers, etc. The standard ISO9001 mostly attests to these. We offer a wide range of indexable tools and inserts, including:

- Turning tools

- Milling tools

- Drilling tools

- Spare parts for indexable tools

- Turning inserts

- Milling inserts

- Drilling inserts

- Cut-off, threading, and grooving systems

At HVH, we work closely with manufacturers to provide superior customer service and engineering support.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Manufacturers

In the world of machining, efficiency and precision are paramount. To achieve optimal results in general-purpose machining and special applications, one must rely on high-quality tools and inserts. We will discuss indexable tools and inserts, highlighting their significance, types, and applications. We explore the various offerings in this category, including turning tools, milling tools, drilling tools, spare parts, and inserts for turning, milling, drilling, cut-off, threading, and grooving systems.

What are Indexable Tools?

Indexable tools are cutting tools with replaceable inserts, also known as indexable inserts, attached to their cutting edge. These inserts are designed to be easily replaced when worn or damaged, offering cost-effectiveness and efficiency in machining processes.

Indexable inserts are the heart of indexable tools. Made of carbide, they provide superior hardness and wear resistance. These inserts come in various shapes, sizes, and coatings, catering to specific machining needs.

Types of Indexable Tools

Turning Tools

Turning is a fundamental machining process that involves the removal of material from a rotating workpiece. Indexable turning tools offer versatility and excellent performance in facing, contouring, and external or internal turning operations.

Milling Tools

Milling is the process of removing material using rotary cutters. Indexable milling tools excel in slotting, shoulder milling, and face milling tasks, ensuring smooth and accurate results.

Drilling Tools

Indexable drilling tools are designed for creating holes with precision and reliability. They come in various designs, such as U-drills and indexable spade drills, to accommodate diverse drilling needs.

Spare Parts for Indexable Tools

To keep machining operations running smoothly, it's crucial to have access to spare parts for indexable tools. These include clamps, screws, and wedges for securely fastening the inserts.

Types of Indexable Inserts

Turning Inserts

Turning inserts come in different geometries to suit various turning applications, such as roughing, finishing, and threading. They are engineered to withstand heat and provide excellent chip control.

Milling Inserts

Milling inserts are crafted to handle the dynamic forces involved in milling operations. Whether it's high-speed milling or heavy-duty tasks, these inserts ensure stability and accuracy.

Drilling Inserts

Drilling inserts are optimized for the challenges of hole-making, offering efficient chip evacuation and precise hole diameters.

Cut-off, Threading, and Grooving Inserts

These inserts are tailored for specialized tasks like parting off, threading, and grooving, enabling clean and precise cuts.

Advantages of Indexable Tools and Inserts

Cost-Effectiveness

The replaceable nature of indexable inserts reduces the need for frequent tool changes, leading to cost savings over time.

Versatility

Indexable tools and inserts can handle various tasks, reducing the need for multiple tools and streamlining machining processes.

Precision

The rigid design and high-quality materials of indexable inserts ensure consistent and accurate results in machining.

Conclusion

Indexable tools and inserts play a pivotal role in modern machining, elevating efficiency and precision to new heights. From turning and milling to drilling and specialized operations, these cutting-edge products cater to a wide array of applications. By choosing the right indexable tools and inserts, machinists can enhance productivity, reduce costs, and achieve outstanding results.