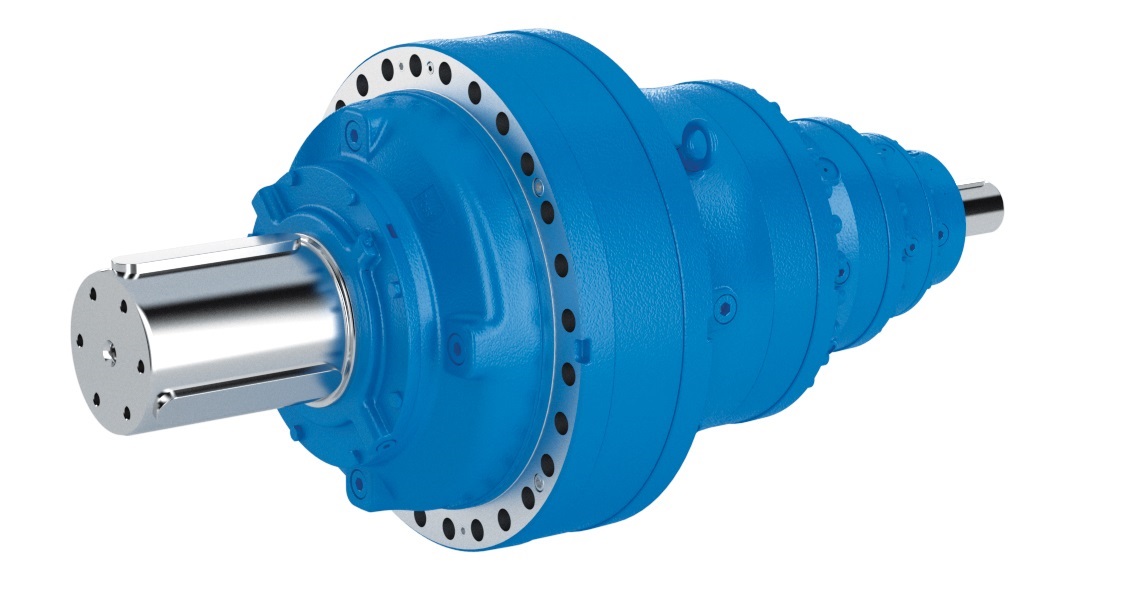

Installation of Planetary Gear Reducers by Rossi

Image source https://www.rossi.com

In the previous post, we talked about what Planetary Gear Reducers by Rossi are and what steps must be taken before installation. In this post, we'll discuss the installation process and the maintenance of Planetary Gear Reducers. Once you go through the verification list before installation and everything is ok, you move on to installation itself.

Installation

Screws and tightening torques

According to the design and size stated on the nameplate, use screws and tightening torques; at least class 10.9 is necessary, but in case of heavy stresses, alternate loads, and shocks, use class 12.9 (class 8.8 can be used if M2 < 70% × Mn2).

The screws must be equipped with ISO 7089 washers (300 HV min.).

Be careful with the tightening of the 12.9 screws. Over-tightening can damage them.

Flange mounting

Before mounting, pay attention to clean, carefully mating surfaces.

In the presence of external radial loads or torque required M2 >= 0,7 × MN2, apply to lock adhesives.

Gear reducer mounting with slewing outputs

In the case of gear reducers with slewing outputs (output design R-S-H), to assure a correct running and an excellent power transfer between gear reducer and machine, the gear reducer requires a rigid connection structure withstanding the radial loads.

Shaft mounting arrangements

When shaft mounted, the gear reducer must be supported both axially and radially by the shaft end of the driven machine as well as anchored against rotation only using a reaction having freedom of axial movement and sufficient clearance in its couplings to permit minor oscillations – always in evidence – without provoking dangerous overloads on the gear reducer.

Hollow shaft mounting with shrink disc

Installation

– carefully degrease the surfaces of the hollow shaft and shaft end of the driven machine to be fitted

– mount the shrink disc on the gear reducer hollow shaft by lubricating first only the external surface of the hollow shaft

– slightly tighten the first group of three screws positioned at about 120°

– mount the gear reducer on the machine shaft end; insert the shaft slowly to allow an air escape

– gradually and uniformly tighten using a dynamometric wrench by a continuous sequence (not crossing) using approximately ¼ turns for several passes until ¼ turns can no longer be achieved

– continue to apply over-torque for 1 or 2 more passes and at the end, verify the bolt tightening torque

– when having heavy-duty cycles with frequent reversals, verify the bolt tightening torque again after some hours of running.

Meshing clearance adjustment

To adjust the meshing clearance, it is advisable to place itself in the initial minimum clearance condition, which can be obtained by making a point of maximum eccentricity on the gear reducer face:

- towards the center of the rack in case of internal gear;

- at 180° concerning the center of the rack in case of external gear.

In this condition, the meshing clearance must not be less than 0,03÷0,04 x m.

It is also advisable that the measured clearance is in the range recommended by the rack manufacturer.

It is advisable to measure the clearance using calibrated thicknesses.

For the lubrication of pinion and rack, use only high-quality grease suitable for the lubrication of gears subjected to high loads such as GADUS S5 T460 1.5

Shell

Product Literature

Operating instructions Planetary gear reducers and gearmotors

Feel free to Contact Us if you have any questions or need more information regarding the maintenance and installation of planetary gear reducers

HVH Industrial Solutions is an authorized Rossi distributor in the US. We work closely with their engineering team to provide superior customer service and engineering support.

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial. He has masters degree in mechanical engineering and over 10 years of experience in mechanical power transmission field.

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut

Vladimir Harutyunyan

Vladimir Harutyunyan is the founder of HVH Industrial ...

Feel free to connect with Vlad on Linkedin: https://www.linkedin.com/in/vladharut